When discussing innovative printing solutions, DTF Transfers stand out as a revolutionary option for businesses seeking efficiency and quality. With their emergence in the custom apparel industry, DTF Transfers offer a compelling alternative to traditional printing methods, providing vibrant prints with minimal waste. As businesses weigh the merits of screen printing vs. DTF, factors such as cost efficiency in printing and print quality comparison become pivotal in their decision-making processes. Furthermore, the adaptability of DTF Transfers aligns well with the growing demand for eco-friendly printing methods, positioning them as a forward-thinking choice for environmentally conscious entrepreneurs. This article delves into the nuances of DTF Transfers, helping you navigate the exciting possibilities they present for your printing needs.

In the realm of printing technologies, the term DTF Transfers refers to Direct-to-Film printing, a method that has gained traction for its dynamic capabilities. This technique, which prints designs onto a specialized film before heat application, is increasingly favored among businesses compared to classic techniques like screen printing. When considering the financial aspects, many assess the affordability of production, especially when evaluating screen printing vs. DTF, as they explore options for maximum cost efficiency in printing. Moreover, this modern approach allows for exceptional print quality with broad fabric compatibility, making it a versatile choice for various applications. As the industry transitions towards more sustainable practices, DTF Transfers illuminate a path towards eco-friendly printing methods, emphasizing the importance of modern innovation in the printing sector.

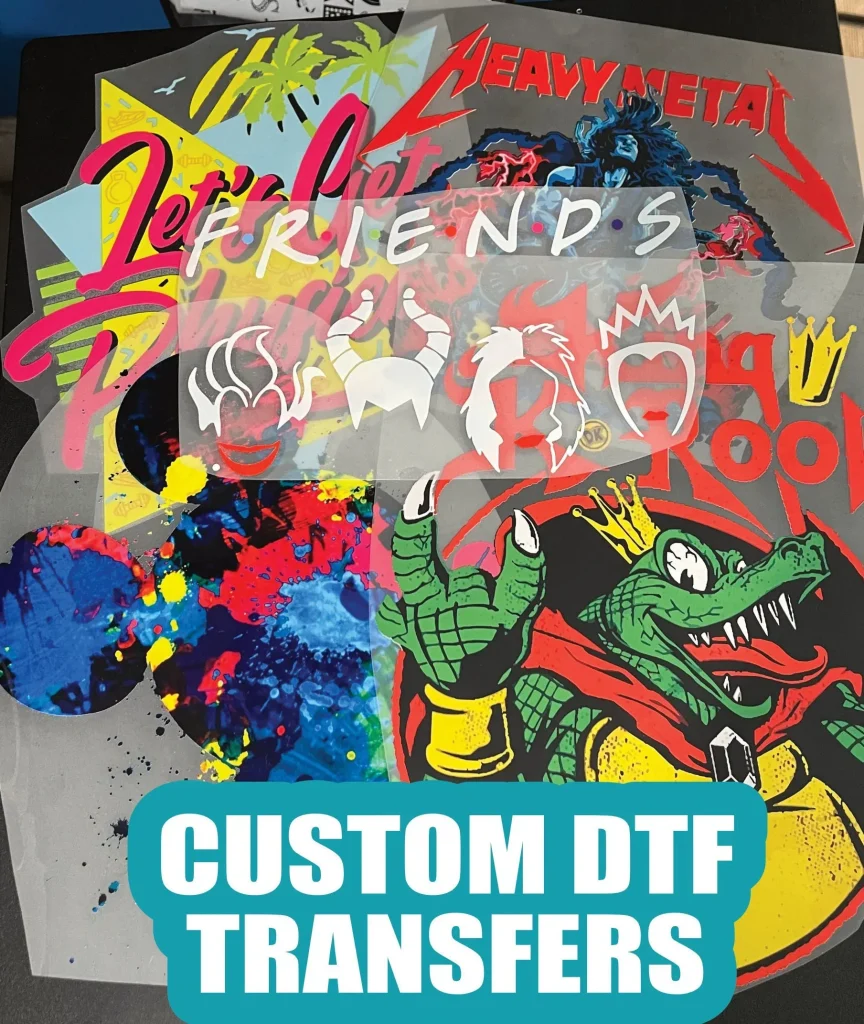

The Rise of DTF Transfers in Modern Printing

In recent times, DTF transfers have surged in popularity and are quickly becoming a frontrunner in the printing industry. This innovative printing technique allows for vibrant, high-quality designs to be printed on a special film before they are heat-pressed onto garments. This process has transformed how businesses approach apparel and custom printing, allowing for easier and faster production times. As small enterprises seek to compete in the expanding market of customized apparel, DTF’s adaptability stands out as an essential advantage over more traditional printing methods.

Additionally, the equipment necessary for DTF printing is becoming increasingly affordable, making it more accessible for startups and small businesses. The low entry barrier, combined with high print quality, positions DTF transfers as a compelling option for those looking to enter the custom printing space. The ability to cater to niche markets with unique designs without significant upfront costs has further solidified DTF’s status as a game-changer in the printing sector.

Comparing Print Quality: DTF vs. Screen Printing

When it comes to print quality, the debate between DTF transfers and traditional screen printing is often a focal point for businesses. DTF technology allows for detailed and colorful prints that can rival, or even surpass, those produced by screen printing techniques. With the right setup, DTF prints maintain high fidelity, ensuring that intricate designs are represented accurately on fabric. This is particularly important for brands aiming for high-quality merchandising, where print appeal can directly impact customer satisfaction.

On the other hand, traditional screen printing is renowned for its durability and longevity, particularly for larger print runs. However, while it excels in producing vibrant colors on solid backgrounds, intricate designs with numerous colors can become costly and complex. For businesses that prioritize detailed artwork or limited runs, DTF can be the superior choice, allowing them to deliver high-quality products without the typical screen printing limitations.

Cost Efficiency of DTF Transfers

Cost efficiency is a critical consideration for any business, especially for those in the printing industry. DTF transfers offer significant savings for small to medium-sized print runs. Unlike traditional screen printing, which requires hefty initial investments in equipment and materials, DTF’s straightforward process leads to lower overall costs. This means businesses can operate with less financial strain, allowing a more flexible approach to order fulfillment.

Moreover, for businesses dealing with custom designs and small orders, DTF provides an attractive model as it eliminates the need for costly setup fees associated with screen printing. This cost-competitive advantage enables brands to cater to diverse client needs without compromising on quality or speed, making DTF an appealing option in a budget-conscious market.

Speed and Turnaround Times in DTF Printing

One of the standout features of DTF transfers is their speed, particularly in fulfilling small orders and customized designs. Companies can produce high-quality prints quickly, which is essential in today’s fast-paced market, where consumer demand for personalization and rapid fulfillment is increasing. The efficient production time of DTF printing positions businesses to capitalize on shorter turnaround requirements that clients increasingly expect.

In contrast, traditional screen printing processes can be slower due to complex setup times that are necessary for each print run, especially when dealing with multiple designs or colors. For businesses focused on promotions, events, or last-minute custom orders, DTF offers a distinct advantage, enabling them to manage workflows more effectively and satisfy clients promptly.

Environmental Benefits of DTF Printing Methods

In a world where sustainability is becoming a critical business focus, DTF transfers stand out as a more environmentally friendly option compared to traditional printing methods. The DTF process typically uses less water and reduces waste compared to screen printing, which is often plagued by water-intensive setups and chemical emissions. This focus on eco-friendliness makes DTF appealing for businesses striving to minimize their environmental footprint and promote sustainable practices.

Additionally, the inks used in DTF printing are frequently designed to be more eco-conscious, further contributing to lower toxicity and waste levels during the printing process. By adopting DTF, businesses not only align themselves with sustainable trends but can also appeal to a growing base of eco-conscious consumers seeking products from responsible brands.

Choosing the Right Printing Method for Your Business

Ultimately, the decision on whether to adopt DTF transfers or stick with traditional methods like screen printing rests on the specific needs of the business. For companies that focus on customization, quick production, and modernity, DTF transfers provide a flexible solution that meets contemporary demands. It allows for easy modifications to designs without significant financial risks, a factor that can greatly benefit smaller boutiques and startups.

However, established businesses that primarily produce large quantities may still find benefits from traditional screen printing, especially when leveraging its cost-per-unit advantages. Thus, businesses must weigh their priorities: Whether they value speed and versatility or are able to capitalize on the long-term investments inherent in traditional methods.

Frequently Asked Questions

What are the key benefits of using DTF Transfers compared to traditional printing methods like screen printing?

DTF Transfers offer several advantages over traditional printing methods, including lower costs for small orders, quicker production times, and vibrant print quality. Unlike screen printing, which requires significant setup and may not be cost-efficient for smaller runs, DTF allows businesses to produce high-quality prints efficiently and at a reduced cost.

How does print quality of DTF Transfers compare to screen printing?

DTF Transfers generally deliver vibrant colors and high resolutions that can match or exceed screen printing. The ability to print on various fabric types enhances their versatility. While screen printing is admired for its durability, advancements in DTF technology also yield good wash resistance, making both methods viable depending on specific business needs.

Is DTF Transfers a more cost-efficient printing method than traditional methods like screen printing?

Yes, DTF Transfers are often more cost-efficient for small orders. Unlike traditional screen printing, which becomes economical only in bulk due to setup costs, DTF technology minimizes these initial expenses, making it an accessible option for startups and small businesses.

Are DTF Transfers eco-friendly compared to traditional printing methods?

DTF Transfers are increasingly recognized as an eco-friendly alternative to traditional printing methods like screen printing. Many DTF processes utilize low-waste materials and sustainable inks, reducing overall environmental impact, while traditional methods often involve higher water usage and chemical emissions.

What industries can benefit most from adopting DTF Transfers over screen printing?

DTF Transfers are particularly beneficial for industries focusing on customization and small batch printing, such as fashion, promotional events, and custom merchandise. As DTF technology supports quick turnaround times for personalized orders, it caters perfectly to businesses with fast-moving consumer demands.

What factors should businesses consider when choosing between DTF Transfers and screen printing?

When choosing between DTF Transfers and screen printing, businesses should consider their order volume, desired print quality, cost efficiency, turnaround times, and environmental impact. DTF is ideal for smaller runs and customization, while screen printing may be more advantageous for large orders where durability and cost-per-unit are essential.

| Key Point | DTF Transfers | Traditional Methods |

|---|---|---|

| Overview | Prints designs onto film, then heat-presses onto fabric. Offers high versatility and rapid output. | Includes techniques like screen printing, heat transfer vinyl (HTV), and direct-to-garment (DTG) printing. Proven effectiveness but slower for smaller runs. |

| Cost Efficiency | Lower upfront costs and quick fulfillment for small orders. Economical for startups. | More economical in bulk production with longer setup times. Higher initial investments required. |

| Print Quality | Delivers vibrant colors, high resolution, and versatility across fabric types. Good wash durability. | Offers durability but may not match the vibrancy of DTF. Quality can suffer in smaller runs due to setup complexity. |

| Speed of Production | Fast production times for smaller orders. Excellent for customization. | Slower setup process, better suited for large orders than small. |

| Environmental Impact | More eco-friendly options and practices. Utilizes low waste materials and eco-friendly inks. | Higher water usage and potential chemical emissions, raising environmental concerns. |

Summary

DTF Transfers represent a modern solution for businesses looking to enhance their printing capabilities. Their cost efficiency, fast production times, vibrant print quality, and eco-friendly approach make them a compelling choice for small or customizing operations. On the other hand, traditional printing methods still hold value for larger projects requiring batch processing. Businesses must weigh the specifics of their requirements carefully to choose the most appropriate method, ensuring they align with operational goals and customer satisfaction.