DTF printing cost is a pivotal consideration for designers, print shops, and startups looking to scale garment customization. Understanding the DTF printing cost breakdown helps you price accurately, balance margins, and decide whether to invest in a higher-end DTF printer cost. From film costs to ink, pre-treatment, and labor, each element influences the price per shirt DTF. Comparisons with other methods, such as DTG, reveal how DTF film cost and overall per-unit economics stack up against the DTG vs DTF cost scenario. By the end of this guide, you’ll see practical tips to optimize the DTF printing cost without compromising quality.

Beyond the phrase DTF printing cost, consider the broader cost structure of fabric transfers that use film, ink, and heat-setting. LSI-friendly terms like transfer media pricing, substrate-ready film charge, and per-garment economics help you forecast quotes without fixed jargon. As order size grows, the fixed costs tied to machinery, maintenance, and setup are spread thinner, lowering the cost per unit. Evaluating the investment in a dedicated DTF printer cost against ongoing consumables frames the decision for shops aiming to scale. In practice, a thoughtful pricing approach combines material efficiency with batch planning to maintain quality while staying competitive.

DTF Printing Cost: A Comprehensive Driver Breakdown

DTF printing cost is not a single number; it’s a composite of four main categories: material costs, machinery and depreciation, labor and time, and overhead. Understanding how each category contributes helps you price projects accurately and protect margins. In practice, referencing the DTF printing cost breakdown can guide decisions about supplier choices, batch sizes, and workflow design, ensuring you’re accounting for all inputs from film to finished shirt.

Material costs drive the per-shirt base and include DTF film, inks, adhesive powder, and substrates. How you source film quality and roll size directly affects the unit price, while depreciation and maintenance set the floor for what you must recover per piece. By tracking these components together, you’ll see why larger runs spread fixed costs more efficiently, lowering the cost per shirt even when design complexity remains high. This is why a clear DTF printing cost breakdown matters for budgeting and quotes.

DTF Film Cost and Its Impact on Per-Shirt Pricing

DTF film cost can be a dominant variable in the per-shirt calculation, especially in small runs. Film price varies by quality, thickness, and roll length, and the transfer film is consumed with every print. Suppliers’ pricing tiers and waste influence the actual cost per shirt more than you might expect.

To mitigate film-driven swings, optimize layout, reduce waste with efficient paneling, and evaluate film types for density and adhesion. Reliable film cost management is part of the larger DTF printing cost breakdown, and choosing the right film can improve color fidelity without inflating price per shirt DTF.

Price per Shirt DTF: Calculating Per-Shirt Cost for Small and Large Runs

A practical way to estimate price per shirt DTF is to sum inputs by batch and allocate shared costs across the number of shirts. Start with material costs per batch, add machine-related costs per shirt, estimate labor, and then assign overhead per unit. This mirrors the method described in the cost framework and helps you create transparent quotes.

Small runs typically carry higher per-shirt costs because fixed expenses are spread over fewer units, whereas large runs benefit from efficiency. By modeling both scenarios, you can set price tiers that reflect true economics and still win business on simpler designs.

DTG vs DTF Cost: How Transfer Method Choice Impacts Your Bottom Line

DTG vs DTF cost comparisons hinge on ink consumption, setup time, and color-matching requirements. DTF tends to be more cost-effective for intricate, multi-color designs across many shirts, thanks to predictable film and ink usage, especially at scale. But it isn’t universally cheaper; the exact costs depend on your equipment and workflow.

DTG often involves higher ink usage and longer color-mixing times, which can raise price per shirt DTF for certain runs, particularly on darker garments. When quoting, compare total cost of ownership, including printer cost, maintenance, and energy, to ensure you’re reflecting true DTG vs DTF cost realities.

DTF Printer Cost: Understanding Capex, Depreciation, and Long-Term Impact

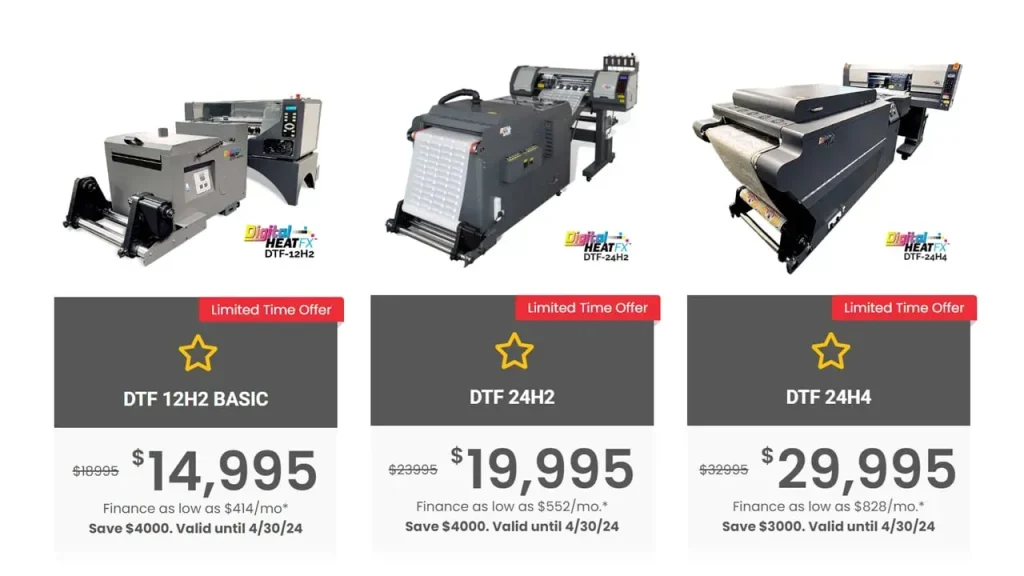

The upfront DTF printer cost is a major anchor for profitability. Beyond the sticker price, you must account for maintenance, printhead replacements, and software licenses. Depreciation and amortization distribute this capital expense across the expected output, shaping the per-shirt economics, particularly for smaller shops with lower monthly volume.

To optimize, plan for a realistic lifespan and maintenance cadence, and quantify how many shirts you must print to break even on the asset. When you track DTF printer cost alongside ongoing consumables, it’s easier to set sustainable pricing and avoid shocks when the machine needs service or upgrades.

Cost-Savvy Strategies: Reducing DTF Printing Cost Without Sacrificing Quality

Several levers exist to lower the DTF printing cost while maintaining quality. Batch planning, smarter layout optimization, and regular calibration can shave material waste and reprints. Automating or streamlining pre-press and post-processing also reduces labor per shirt and improves throughput.

Investing in bulk purchases, negotiating supplier terms, and choosing high-yield inks and film with favorable cost-per-volume metrics are practical ways to lower the DTF printing cost breakdown over time. Pair these tactics with fixed-cost management and reasonable pricing, and you’ll sustain profitability even as you scale.

Frequently Asked Questions

What factors are included in the DTF printing cost breakdown and how should I estimate the per-shirt price?

DTF printing cost breakdown includes material costs (DTF film cost, inks, adhesives, and substrates), machinery depreciation (DTF printer cost and maintenance), labor (prep, print, post-processing), and overhead (electricity, facilities, waste). To estimate the per-shirt price, tally all inputs for a batch, allocate depreciation and overhead by your monthly output, add labor, and divide by the shirts produced. This approach shows how volume affects the DTF printing cost per shirt.

How does DTF film cost influence the price per shirt DTF, especially for small runs?

DTF film cost is a major part of material costs and can swing the DTF printing cost per shirt, particularly in small runs. Since film is consumed with every transfer, the per-shirt film cost can be a large share of the total when you print few shirts. To optimize, choose film with favorable cost per square inch, minimize waste, and consider larger batch planning to spread the film cost over more shirts.

DTG vs DTF cost: which method is cheaper per shirt for high-color designs?

DTG vs DTF cost varies by design and volume. DTF printing cost per shirt often benefits from film and ink efficiency for high-color, detailed designs, especially in small-to-mid runs, while DTG can incur higher ink consumption and color-mixing setup costs. For multi-color transfers on many shirts, DTF price per shirt can be more favorable, depending on your equipment and supplier prices.

How does DTF printer cost affect the overall DTF printing cost and profitability?

DTF printer cost is a major fixed expense. Include upfront printer cost and ongoing maintenance in depreciation (DTF printer cost) and then allocate across monthly output. Higher monthly production lowers per-shirt cost; keeping the printer calibrated reduces waste and reprints, improving profitability under the DTF printing cost model.

What is the price per shirt DTF when comparing large vs small batch orders?

Price per shirt DTF drops with larger batch orders because fixed costs like depreciation and overhead are spread across more units. In practice, a small run (e.g., 10 shirts) can be much higher per shirt, while a larger run (e.g., 100 shirts) reduces the per-shirt cost significantly, as illustrated by typical cost breakdowns in the guide.

What steps can I take to reduce DTF printing cost without sacrificing quality?

To reduce the DTF printing cost, focus on: 1) Optimizing material usage and choosing efficient DTF film; 2) Improving printer efficiency and maintaining calibration to lower ink waste and reprints; 3) Batch planning to spread fixed costs; 4) Automating pre-press or post-processing steps to cut labor; 5) Sourcing smarter through bulk film and ink deals; 6) Monitoring waste and adjusting purchasing and pricing as needed.

| Topic | Key Points |

|---|---|

| Material costs | – DTF film is consumed with every print; prices vary by quality, roll size, and supplier. Film costs can substantially impact per-shirt cost in small batches. – Inks and consumables: special pigment inks for DTF, adhesive powder, and post-processing supplies; ink yield and color density affect quantity, waste, and overall cost. – Substrates and pre-treatment: garments or textiles may require pre-treatment or heat-setting; textile type and sleeve coverage influence waste and curing time. – Miscellaneous consumables: cleaning sheets, squeegees, and small items contribute incrementally but add up across orders. |

| Machinery and depreciation | – Printer cost: upfront price and upgrades. – Maintenance and consumables: routine maintenance, printheads, and calibration. – Depreciation and amortization: spreading upfront cost over machine lifespan. – Curing and finishing equipment: heat presses, conveyors, and drying stations add fixed costs. |

| Labor and time | – Prep time: file prep, color corrections, layout setup. – Print time: actual design printing and test prints. – Post-processing: curing, trimming, quality checks. – Handling and packaging: preparing shirts for shipping or pickup. – Labor varies with artwork complexity, colors, and color-matching needs. |

| Overhead and other costs | – Electricity and water usage: energy for printing and curing; scales with volume. – Facility costs: rent, insurance, admin expenses allocated per project. – Waste and rejects: misprints waste materials and time; include a rejection rate in pricing. – Software and licenses: RIP software, color-management tools, firmware updates. |

| Estimating per-shirt cost: method | – Gather material costs per batch and divide by shirts in batch to get material per shirt. – Estimate machine-related cost per shirt: depreciation + maintenance divided by expected monthly output. – Account for labor per shirt: total labor hours per batch × labor rate ÷ shirts. – Add overhead per shirt: monthly overhead ÷ monthly production. – Sum components: material per shirt + machine per shirt + labor per shirt + overhead per shirt. |

| Small-batch example (10 shirts) | – Material costs per batch: $6 (film/ink) + $2 (adhesive/consumables) = $8; per shirt = $0.80 – Machine depreciation/maintenance: $150/month; 15 shirts/month; per shirt = $10.00 – Labor: 1.5 hours × $20/hour = $30; per shirt = $3.00 – Overhead: $400/month ÷ 15 shirts = $26.67 per shirt – Estimated DTF cost per shirt: ≈ $40.47 |

| Large-batch example (100 shirts) | – Material costs per batch: $60 (film/ink) + $20 (adhesives) = $80; per shirt = $0.80 – Machine depreciation/maintenance: $150/month; per shirt = $1.50 – Labor: 2.5 hours × $20/hour = $50; per shirt = $0.50 – Overhead: $400/month ÷ 100 shirts = $4.00 per shirt – Estimated DTF cost per shirt: ≈ $6.80 |

| Interpreting results | – Batch size dramatically changes per-shirt cost: large runs spread fixed costs more efficiently, lowering price per shirt. – Small runs face higher per-shirt overhead and typically longer labor per unit. |

| DTF cost vs other methods | – DTF costs benefit from economies of scale, especially for high-color designs, due to predictable film/ink usage across runs. – DTG may have higher ink consumption and setup for complex designs; per-shirt cost can be higher or lower depending on ink prices and maintenance. – For small-to-medium runs with high color complexity, DTF can be more cost-efficient; very large runs may favor DTG depending on context. |

| Pricing strategy | – Build tiered pricing: lower per-shirt pricing for larger runs; baseline for small orders. – Factor in color/finish: full-color, soft-hand finishes may justify higher margins. – Include setup/proofs: setup fees or design surcharges for proofs/color matching. – Volume discounts with suppliers: bulk film/ink purchases to reduce per-unit costs and stay competitive. |

| Ways to reduce cost | – Optimize material usage: choose appropriate film and layout to minimize waste. – Improve printer efficiency: calibration, high-yield inks, regular maintenance. – Batch planning: produce in larger batches where possible. – Automation: automate pre-press or post-processing to reduce labor per shirt. – Smarter sourcing: bulk buying, quality film/ink with favorable cost-per-unit. |

| Common pitfalls | – Underestimating labor: track hours accurately and price accordingly. – Ignoring waste: include potential reprints in pricing. – Overcomplicating color management: complex color matching can waste time/materials. – Failing to update pricing: refresh quotes as material/energy costs change. |

Summary

DTF printing cost is driven by material costs, machinery depreciation, labor, and overhead, with batch size shaping the per-shirt price. This table highlights the major cost categories, how each contributes, and strategies to price and optimize profitability. Larger runs spread fixed costs more efficiently, reducing the per-shirt cost, while small runs tend to carry higher per-unit overhead. Use these insights to craft transparent quotes, manage workflows, and maintain quality without sacrificing margins.