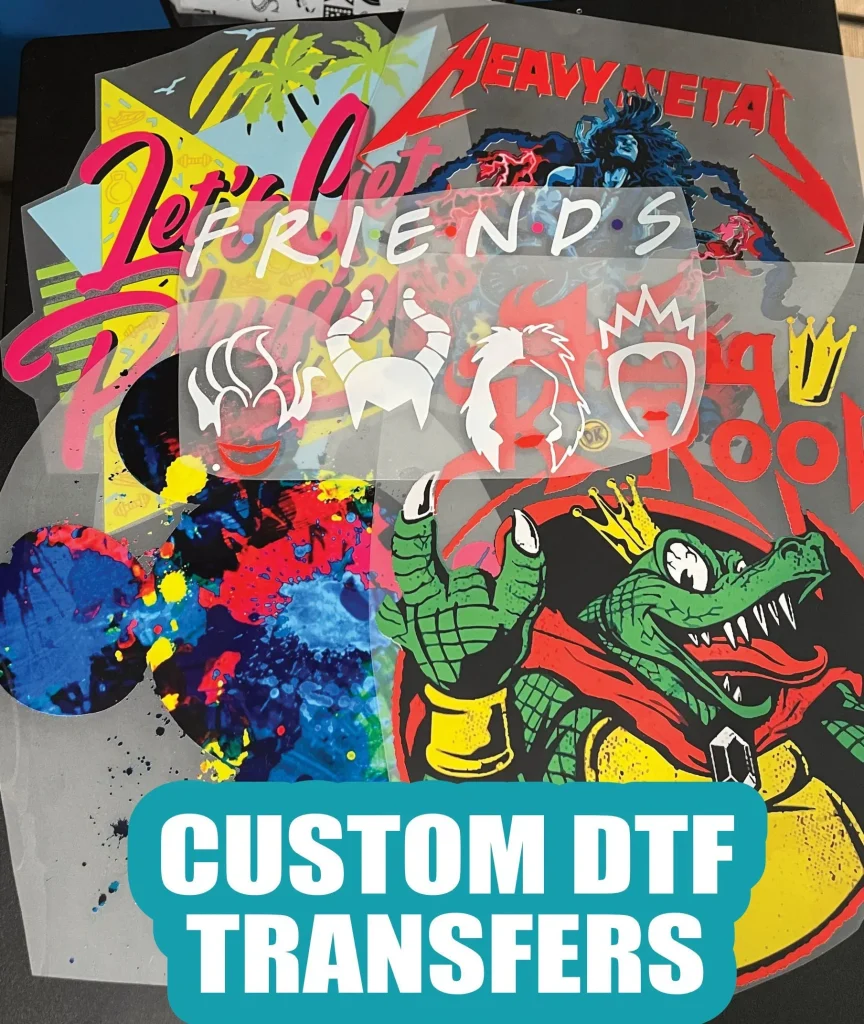

DTF Transfers, or Direct to Film transfers, are rapidly becoming the go-to technique for custom apparel and fabric printing, enabling designers to create eye-catching designs with stunning detail. This innovative printing method involves transferring high-quality, vibrant images onto a film that can then be applied to various fabrics through heat and pressure. DTF Transfers not only allow for intricate and colorful designs but also offer durability and versatility, making them ideal for any apparel project. Whether you’re looking to start a small business or simply want to personalize your wardrobe, mastering this heat transfer technique will set you apart from the competition. Join us in exploring the essential strategies to harness the full potential of DTF Transfers for outstanding custom apparel design.

The world of custom fabric printing has been transformed with the introduction of direct film transfers, a cutting-edge method that captivates both designers and consumers alike. This approach allows for the application of detailed graphics and designs directly onto textile substrates, resulting in stunning visual effects that catch the eye. Utilizing a heat transfer technique, it’s possible to achieve remarkable color vibrancy and clarity, which are essential for high-quality custom apparel design. Whether referred to as film transfer or heat transfer prints, this versatile printing technology opens doors to endless creative possibilities in the fashion and merchandising industries. In the following sections, we’ll uncover everything you need to know about maximizing your potential with this innovative fabric printing solution.

Unlocking the Power of Direct to Film (DTF) Transfers

Direct to Film (DTF) transfers represent a significant innovation in the realm of fabric printing, allowing designers to create visually striking apparel with ease. This technique not only enhances the vibrancy and clarity of printed designs but also offers unparalleled versatility. DTF printing works by transferring high-quality inks onto a film which is then heat-pressed onto garments, resulting in a finished product that is as durable as it is bright. The ability to print complex designs with fine details has paved the way for custom apparel design to flourish, catering to both niche markets and wider commercial demands.

Moreover, DTF transfers cater to a range of fabrics, from cotton to polyester and everything in between, making it an attractive option for creators looking to expand their product lines. The process is relatively straightforward compared to traditional methods like screen printing, which can be limited by the number of colors and the intricacy of designs. With DTF, all you need is a high-resolution graphic, and you’re set to produce stunning, customized applications that can stand out in a crowded market.

Essential Tools for Creating Eye-Catching Designs

To start creating eye-catching designs using DTF transfers, it is imperative to equip yourself with the right tools and software. Programs such as Adobe Illustrator or CorelDRAW are excellent for crafting high-resolution vector graphics, which are essential for optimal print quality. The use of these design tools coupled with a quality inkjet printer that supports DTF technology will enable you to produce intricate and vibrant designs that capture attention and convey your unique style.

Investing in high-quality heat presses is equally important, as achieving the right temperature and pressure is crucial for ensuring the longevity and fidelity of your prints. By having a solid understanding of your tools, you can streamline your workflow and produce custom apparel designs that not only look great but are also built to last, making them practical for everyday wear.

Color Optimization Techniques for DTF Printing

In the world of DTF transfers, color optimization is not just a suggestion; it’s a necessity. The colors you choose should not only reflect your brand’s identity but also be suitable for the fabric you plan to print on. Utilizing color profiles specific to your printer and transfer film can dramatically affect how colors appear on the final product. It is also beneficial to conduct test prints on various substrates to ascertain how the colors render across different fabric types.

Additionally, vibrant colors can greatly enhance the visual appeal of your designs, making them more attractive to potential customers. Layering colors thoughtfully and balancing bright tones with subtle shades can create depth in your designs, giving them a professional edge. By experimenting and fine-tuning your color choices, you can ensure that each print pops, capturing the attention of anyone who sees it.

Strategic Typography for DTF Transfers

Typography plays a fundamental role in the design process, especially with DTF transfers. The fonts you select can greatly impact the readability and overall aesthetics of your apparel. It’s important to choose bold, high-contrast fonts that can withstand the heat transfer process without losing quality or becoming illegible. Opting for simpler font styles can help maintain clarity and ensure that even small text remains sharp and recognizable after printing.

Moreover, consider the emotional tone that different fonts convey. A playful script might be suitable for a casual t-shirt design, while a clean sans-serif is ideal for professional attire. By aligning typography with your design’s intent and the target audience, you can create a cohesive look that resonates with consumers, enhancing the appeal of your custom apparel offerings.

Choosing the Right Fabric for DTF Application

Selecting the right fabric for your DTF transfers is crucial, as the fabric will influence the final appearance and feel of the design. Fabrics such as cotton blends and polyester are widely regarded for their compatibility with DTF printing technologies. The texture and color of the fabric can significantly impact how well the colors turn out, making it essential to match the fabric characteristics with your design requirements.

Before proceeding with full-scale production, conducting test presses on different fabric types can help determine the best material for your specific designs. Understanding how different fabrics interact with the DTF process allows you to refine your selections and achieve the best possible results, ensuring that your designs maintain their vivid colors and high-resolution details across varying mediums.

Mastering Heat Transfer Techniques for Optimal Results

Mastering the heat transfer technique is pivotal to the success of your DTF projects. The heat press settings, including temperature, pressure, and time, must be carefully calibrated to achieve a secure bond between the film and the fabric. Using a heat press that allows for precise control will ultimately enhance the durability and quality of your prints.

It’s also beneficial to acclimatize your products and transfer films to the appropriate conditions before initiating the printing process. A well-prepared workspace and equipment can minimize issues during application, leading to hassle-free results that truly reflect the artistry of your designs. Regular maintenance and adjustment of your heat press settings will ensure consistency in quality, leading to a satisfied customer base.

Frequently Asked Questions

What are DTF transfers and how do they work for custom apparel design?

DTF transfers, or Direct to Film transfers, involve printing designs onto a special film which is then heat-pressed onto fabric. This method allows for vibrant color reproduction and high-definition images, making it ideal for custom apparel design. DTF transfers are versatile and can be applied to various fabric types, resulting in eye-catching designs that maintain their quality even after washing.

How can I create eye-catching designs using DTF transfers?

To create eye-catching designs with DTF transfers, start by using high-resolution images and vector graphics to ensure clarity. Optimize colors suited for your target fabric, choose bold typography, and maintain layout balance by using negative space strategically. These steps will help enhance the overall impact of your DTF designs, making them visually appealing and professionally finished.

What types of fabrics are best for DTF transfers?

The best fabrics for DTF transfers include cotton blends and polyester materials. These fabrics tend to exhibit better color fidelity and image quality. Before committing to a large batch, performing test presses on your chosen fabric is essential to assess compatibility and achieve the desired outcome for your DTF designs.

How does color management affect DTF printing quality?

Color management is crucial in DTF printing as it determines how vibrant and accurate your finished designs will be. Using bright and contrasting colors that suit your fabric is important, but be sure to conduct test prints to see how colors render on different materials. This practice ensures consistent results and visually striking DTF prints.

What printer settings are optimal for DTF transfers?

Optimal printer settings for DTF transfers involve adjusting your ink saturation for better color quality, using the correct transfer film, and monitoring temperature and time settings during the heat press application. It’s important to experiment and fine-tune these settings according to the type of fabric to achieve the best results for your DTF designs.

What are some tips for ensuring durability in DTF designs?

To ensure durability in DTF designs, choose high-quality transfer films, use the correct heat press settings, and perform test runs before full production. Additionally, applying a protective layer over the print can enhance longevity. By maintaining these practices, your DTF transfers will withstand washing and wear while retaining their vibrant appearance.

| Key Points | Details |

|---|---|

| Understanding DTF Transfers | DTF transfers involve printing designs onto a specialized film that can adhere to various fabrics using heat and pressure, offering high-definition images. |

| Start with Quality Designs | Use high-resolution images (300 DPI recommended) and vector formats for clear, scalable prints. |

| Optimize Your Colors | Conduct test prints to ensure vibrant colors match different fabric types. |

| Typography Matters | Choose bold, readable fonts and avoid complex typography for better transfer quality. |

| Consider Layout Balance | Ensure a balanced design with strategic use of negative space to enhance aesthetics and legibility. |

| Choose the Right Fabric | Cotton blends and polyester are recommended; conduct test presses for compatibility. |

| Optimize Your Printing Settings | Adjust printer settings for ink saturation and monitor temperature during heat press. |

| Testing is Key | Conduct test runs to ensure design adherence and assess color accuracy before larger production. |

| Additional Resources | Utilize blogs, tutorials, and community forums to enhance DTF transfer skills. |

Summary

DTF Transfers have revolutionized the way custom designs are created, making them an essential tool for anyone in the apparel printing industry. This method provides exceptional image clarity and durability, enabling designers to take creative risks while ensuring high-quality outputs. By mastering the key aspects of DTF Transfers, including design quality, color optimization, typography, layout, and fabric selection, creators can expand their capabilities and produce stunning garments that stand out in the market. As you explore this innovative printing technology, remember to embrace learning and experimentation to truly harness the full potential of DTF Transfers.