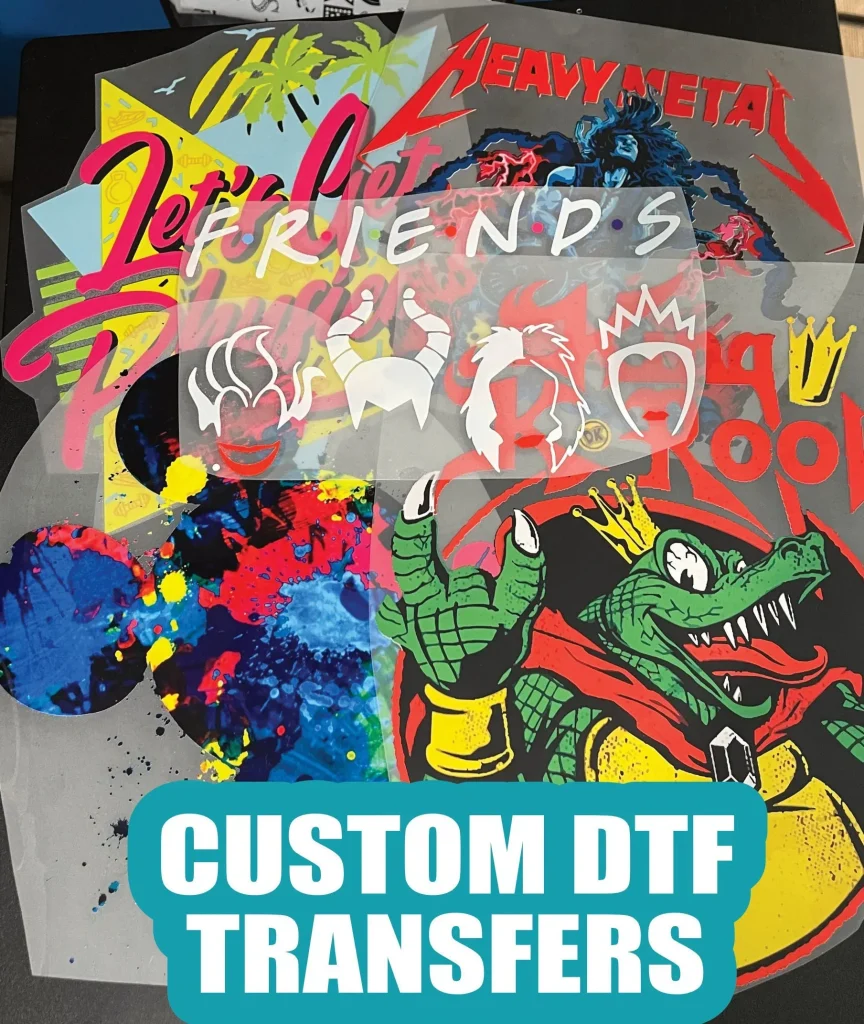

DTF transfers, short for Direct-to-Film transfers, are revolutionizing the way we approach custom transfer printing in the garment industry. This cutting-edge technology combines vibrant graphics with ease of use, making it an attractive option for both beginners and seasoned crafters. In this comprehensive guide on DTF printing for beginners, we’ll unveil the essential supplies required for success, including DTF printing supplies and equipment. You’ll learn how to use DTF transfers effectively to create stunning, durable designs on a variety of materials. Ready to jump into the world of DTF printing? Let’s explore the limitless creative possibilities that await you!

Known as Direct-to-Film printing, DTF transfers are gaining traction among crafting enthusiasts due to their versatility and vibrant output. This modern printing technique allows users to print designs onto a special film, which can then be applied to a range of substrates, from cotton to polyester blends. For those embarking on their creative journey, knowing how to utilize DTF transfers effectively can unlock a new realm of custom printing projects. Whether you are a budding entrepreneur or a hobbyist, understanding the essentials of DTF printing is crucial to achieving beautiful, long-lasting results. Join us as we delve deeper into this exciting method and discover its advantages over traditional printing techniques.

What is DTF Printing and How Does It Work?

DTF printing, or Direct-to-Film printing, is a groundbreaking method that enables designers to transfer high-quality graphics onto a variety of textiles and materials. The process begins with printing a design onto a specialized film using a DTF printer that employs unique inks. This method distinguishes itself by allowing for the transfer of intricate and vibrant designs that are durable and long-lasting. Unlike traditional printing methods that often require expensive and specialized substrates, DTF printing can work with an array of materials including cotton, polyester, and blends, making it a preferred option for many crafters.

To successfully implement DTF printing, understanding the entire workflow is essential. After the design is printed onto the film, an adhesive powder is applied which aids in the transfer when heat is applied. This versatility is a significant advantage, as it simplifies the printing process compared to methods like sublimation that limit you to polyester fabrics. Understanding how DTF transfers work gives you the foundational knowledge needed to innovate and create without the limitations of traditional printing.

Essential Equipment for DTF Transfers: What You Need to Get Started

When embarking on your DTF journey, acquiring the right equipment is vital to ensuring success. The primary tool you’ll need is a DTF printer, which is specially designed to handle unique inks and produce high-quality prints on transfer films. Additionally, specialized DTF transfer films are necessary—they come coated in a way that allows for an efficient heat transfer process. Investing in a quality heat press is equally important; it is crucial for properly adhering your design onto the substrate.

Lastly, do not overlook the importance of adhesive powder and design software. The adhesive powder is what bonds the print to the fabric, ensuring durability and vibrancy once the transfer is complete. Meanwhile, being proficient in design software allows you to create or modify graphics effectively, ultimately leading to more professional-looking results. Together, these elements form the backbone of a successful DTF printing operation.

The DTF Transfer Process: Step-by-Step Guide for Beginners

Understanding the DTF transfer process is essential for any beginner looking to leverage this innovative printing technique. The process begins with printing your design onto a DTF transfer film. It’s crucial to adjust printer settings properly to achieve optimal quality and ensure your design pops with vibrant colors. Once printed, sprinkle adhesive powder over the film to prepare it for heat application.

The next steps involve curing the adhesive, which is done by using a heat press to melt the powder onto the printed design. This step is critical, as it ensures a strong bond between the ink and the fabric. After curing, place the film onto your substrate and apply heat according to the specifications. Finally, once the design cools, carefully peel away the transfer film to reveal the intricately transferred design. This method ensures a high-quality, durable print that adheres securely, making it perfect for both personal projects and commercial ventures.

Benefits of DTF Transfers for Crafters and Entrepreneurs

DTF transfers are revolutionizing the way crafters and small business owners approach custom printing. One of the foremost benefits of this method is its adaptability—DTF printing can be applied to a wider variety of materials than other techniques such as sublimation, which is limited to synthetic fabrics. This versatility means you can easily create personalized items across various textiles without worrying about material compatibility.

Furthermore, DTF transfers are known for their durability and vibrancy. The prints are resistant to cracking and fading, ensuring that your designs remain vibrant even after multiple washes. This quality makes it an excellent choice for items intended for resale, as it enhances product value. For beginners, DTF transfers offer a straightforward and user-friendly approach to custom transfer printing, making it accessible for those just starting their business or craft journey.

DTF vs. Traditional Printing Methods: Which Is Better?

When comparing DTF printing to traditional methods such as screen printing or heat transfer vinyl (HTV), several advantages become evident. One primary distinction is the flexibility it offers in materials; unlike sublimation, which requires specific types of fabrics, DTF printing can be used on cotton, polyester, and hybrid fabrics. This flexibility opens up a multitude of possibilities for crafters and entrepreneurs, as they can cater to various customer needs.

Another compelling factor is the ease of application with DTF transfers. Beginners can quickly grasp the process compared to the complexities often associated with traditional screen printing, which involves multiple steps and equipment setup. Additionally, the vibrancy and longevity of DTF prints surpass many of the traditional options, making them an increasingly popular choice in the custom printing industry. By understanding how DTF compares to traditional methods, you can make informed decisions for your crafting projects.

Tips for Mastering DTF Printing: Best Practices for Beginners

To excel in DTF printing, especially as a beginner, it’s crucial to adopt best practices that enhance your output quality. First and foremost, don’t hesitate to experiment with various designs and substrates. Trying out different combinations can lead to exciting discoveries and improvements in your technique, allowing you to refine your skills. Starting with simple designs is another advisable step—this strategy helps you master the basics before moving onto more intricate projects.

Additionally, investing in high-quality DTF printing supplies, such as transfer films and adhesive powders, cannot be overstated. The quality of your materials directly affects the final output, so always opt for reputable brands. Lastly, staying updated with industry trends and innovations can provide invaluable insights and improve your printing efficiency. By continually learning and adapting, you’re more likely to stay ahead in the ever-evolving world of custom transfer printing.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a printing method where designs are printed onto a special film capable of being heat transferred onto various substrates, such as cotton and polyester. This process offers vibrant colors and intricate designs that are durable and easy to apply, making it a popular choice for both DIY enthusiasts and small businesses.

What equipment do I need for successful DTF printing?

To successfully execute DTF printing, you’ll need a DTF printer, transfer films, a heat press, adhesive powder, and design software. Each of these supplies plays a critical role in ensuring that your DTF transfers are easy to create and adhere well to the targeted substrates.

Can I use DTF transfers on any type of fabric?

Yes, DTF transfers are versatile and can be applied to a range of fabrics including cotton, polyester, and blends. Unlike other printing methods like sublimation, DTF does not require specialty fabrics, making it an excellent choice for various materials.

What are the main advantages of using DTF printing for beginners?

DTF printing offers several advantages for beginners, such as versatility in material options, durability of prints, and the simplicity of the transfer process. These benefits allow newcomers to easily explore custom transfer printing without needing extensive experience or specialized materials.

How do I care for garments printed with DTF transfers?

To maintain the quality of garments printed with DTF transfers, wash them in cold water and avoid bleach or harsh detergents. It’s also recommended to dry these items on low heat or hang them to dry to preserve the vibrancy of the prints and ensure longevity.

What tips do you have for beginners starting with DTF transfers?

Beginners should start with simple designs to master the DTF transfer process. It’s crucial to invest in high-quality DTF printing supplies, experiment with various substrates, and keep up with the latest industry trends to refine your skills and optimize results.

| Aspect | Details |

|---|---|

| What is DTF? | Direct-to-Film printing method involving printing graphics on a film for heat transfer onto various substrates. |

| Advantages | Versatility, simplicity compared to sublimation, vibrant and durable colors. |

| Equipment Needed | DTF Printer, Transfer Films, Heat Press, Adhesive Powder, Design Software. |

| DTF Process Steps | 1. Print Design, 2. Apply Adhesive Powder, 3. Cure Adhesive, 4. Press onto Substrate, 5. Peel and Finish. |

| Comparison | Versatile for various materials, durable prints, easier transfer than sublimation and HTV. |

| Tips for Beginners | Experiment with designs, start simple, use quality materials, stay updated with trends. |

Summary

DTF Transfers provide an exciting avenue for both amateur and professional crafters, allowing creative expression through custom designs with vibrant results. By understanding the fundamental aspects, including the required equipment and the step-by-step process, beginners can easily navigate the world of DTF Transfers. The versatility and durability of DTF printing outshine many traditional methods, making it a popular choice for custom garment decoration. With experimentation and quality materials, anyone can embrace this innovative technology and produce stunning results.