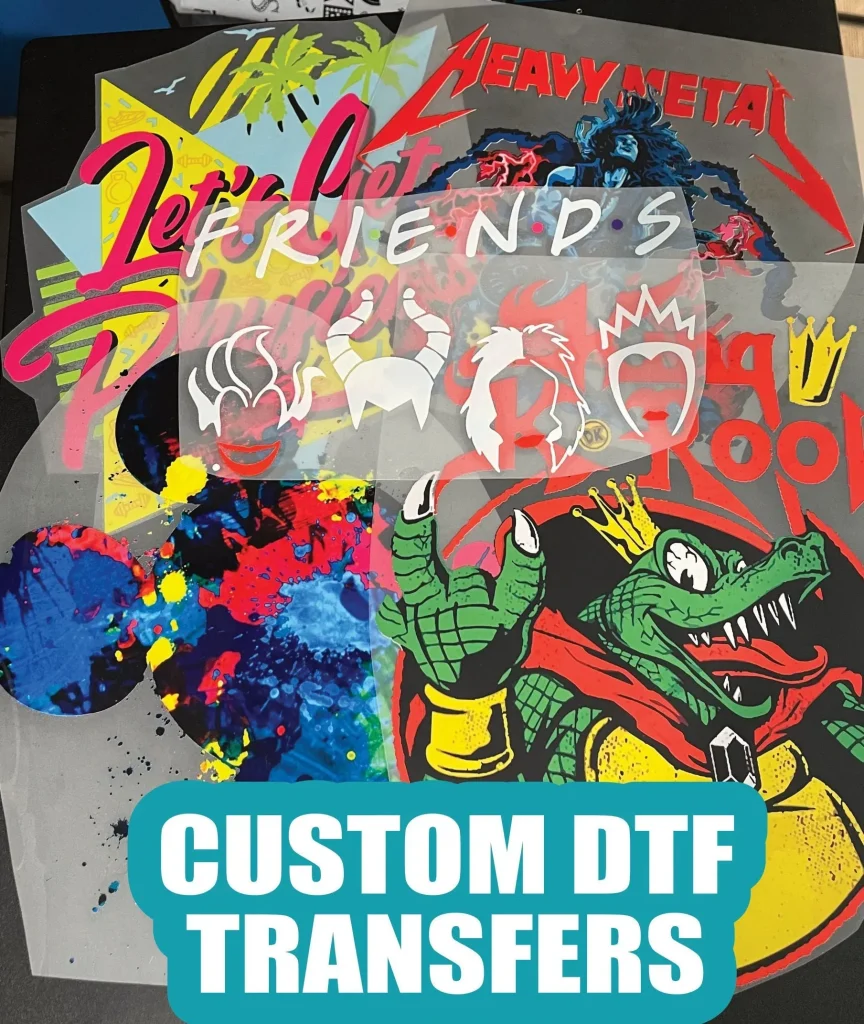

DTF transfers, or Direct-to-Film transfers, are revolutionizing the custom apparel industry by offering unique advantages that traditional printing methods simply can’t match. As the demand for high-quality custom designs continues to grow, understanding the benefits of DTF printing is essential for designers and businesses alike. DTF technology allows for vibrant and durable designs to be printed on a variety of fabrics, making it a versatile solution for custom apparel. This blog post will delve into how DTF transfers elevate design possibilities and contribute to efficiency and cost-effectiveness in apparel production. Whether you’re a small business owner or a passionate designer, exploring the world of DTF transfers could be your gateway to creating stunning, long-lasting garments that resonate with customers.

Direct-to-Film technology, often referred to as DTF printing, is gaining traction as a preferred method for designers seeking innovative printing solutions in the apparel sector. This advanced technique enables the application of bold and intricate designs on diverse materials, appealing to a broad audience of custom clothing enthusiasts. By leveraging the capabilities of DTF transfers, businesses can maximize their efficiency and minimize production costs while delivering high-quality custom pieces. Additionally, the quick turnaround time associated with this printing process allows for an agile response to market trends and customer demands. As personalized fashion continues to thrive, integrating DTF printing benefits into your operations can significantly enhance your competitive edge.

Understanding DTF Transfers and Their Unique Process

Direct-to-Film (DTF) transfers have emerged as a groundbreaking technique in the world of custom printing. This method uses specialized films that capture vivid images, which are then transferred onto fabrics through a unique process involving heat and pressure. Unlike traditional methods that often require specific fabric types, DTF’s versatility enables it to work with a wide range of textiles, making it a favorite among apparel manufacturers. As the demand for custom designs grows, understanding the workflow and technology behind DTF transfers becomes essential for any business looking to thrive in this industry.

The DTF process begins with the printing of designs onto a film using high-quality inks. After printing, a special adhesive powder is applied to the moist print, which is then heated to ensure that it properly adheres to the film. Once this preparation is complete, the film can be pressed onto the desired fabric. This innovation not only allows for vibrant colors and intricate details but also ensures that designs remain intact after multiple washes, appealing to consumers who prioritize quality and durability in custom apparel.

Advantages of DTF Transfers for Custom Apparel

One of the most significant advantages of DTF transfers is their exceptional print quality. When it comes to custom apparel, customers often seek unique designs that reflect their personal style, and DTF technology delivers precisely that. The high-resolution prints produced by DTF transfers are both vibrant and detailed, allowing businesses to showcase complex graphics that stand out. This quality ensures that custom designs become conversation starters, enhancing brand recognition and customer loyalty.

In addition to superior print quality, DTF transfers are also known for their durability. Unlike other printing techniques that may fade or crack after frequent washing, DTF transfers are designed to withstand the rigors of everyday wear. The specially formulated inks bond deeply with the fabric, maintaining their vivid appearance over time. This durability not only satisfies customers but also reduces returns and increases repeat business, benefiting custom apparel companies in a competitive market.

Cost-Effectiveness of DTF Printing

Cost-effectiveness is a critical factor for any business, especially in the custom apparel industry where overheads can quickly accumulate. DTF transfers present a financially savvy solution by utilizing gang sheets—groups of designs printed on one sheet. This method minimizes material and ink waste, greatly reducing costs for businesses. By maximizing resources, apparel companies can maintain profitability while still offering competitive prices to customers.

Additionally, advancements in DTF technology have led to the development of faster printers that can handle large volumes of transfers in a shorter time. This means businesses can produce significant quantities without compromising quality, further enhancing their cost efficiency. As a result, companies can take on more orders, meeting customer demands promptly and establishing themselves as reliable suppliers in the custom design landscape.

Expedited Production Times with DTF Transfers

In the fast-paced world of custom apparel, quick turnaround times can significantly affect customer satisfaction and retention. DTF transfers are advantageous in this respect, as they enable businesses to produce custom designs on demand rapidly. With traditional printing methods, lengthy setup times can hinder responsiveness to customer needs; however, DTF technology minimizes these delays, allowing for an efficient production process.

Companies leveraging DTF printing systems can easily adjust to fluctuating customer demands and last-minute orders. This flexibility not only enhances service delivery but also positions businesses as agile competitors in the market. For instance, businesses that invest in modern DTF printing equipment can provide same-day service or rapid shipping options, making them more appealing to consumers looking for quick solutions for their custom apparel needs.

Broader Market Appeal Through Custom Designs

As personalization trends continue to influence the fashion industry, DTF printing aligns perfectly with the growing demand for custom designs. Businesses that implement DTF transfers can cater to a diverse range of consumer preferences, from intricate graphics to personalized messages. This breadth of application is particularly appealing in sectors like promotional products, where unique designs can set a brand apart from competitors.

Moreover, DTF technology’s ability to handle bulk orders without sacrificing quality means that businesses can attract larger retail clients looking for reliable suppliers. As larger brands seek unique designs in significant quantities, those who adopt DTF transfers can expand their market reach and enhance their business operation. Through strategic marketing and leveraging the benefits of DTF transfers, companies can build a robust portfolio that appeals to both individual consumers and large retailers.

DTF Transfers: The Future of Custom Apparel Printing

As technology innovates, DTF transfers are reshaping the future of custom apparel printing. With advancements in printing technology and techniques, businesses can expect to see even greater improvements in quality, efficiency, and versatility in the production of custom designs. The seamless integration of DTF transfers into apparel production processes paves the way for new opportunities across the fashion industry, enabling designers to transform their creative visions into reality.

Additionally, embracing DTF printing not only meets current consumer demands for high-quality, custom apparel but also positions businesses for future growth. As the market continues to evolve, those who invest in DTF technology will be well-prepared to adapt to emerging trends, ensuring they remain competitive. The potential for customization and scalability in DTF transfers makes them a strategic choice for businesses aiming to thrive in the custom apparel sector.

Frequently Asked Questions

What are the advantages of DTF transfers in custom apparel production?

DTF transfers offer numerous advantages in custom apparel production, including versatility across various fabrics, cost-efficiency through gang sheets, high-quality and durable prints, quick turnaround times, and broader market appeal. This makes DTF printing an excellent choice for businesses looking to enhance their custom designs.

How does DTF printing benefit fabric versatility?

DTF printing benefits fabric versatility by allowing applications on a wide range of materials such as cotton, polyester, and blends. Unlike traditional sublimation, DTF can print on both light and dark fabrics, ensuring vibrant colors and detailed images without compromising quality.

What technology is used in DTF transfers to ensure durability?

DTF transfers use specialized inks that deeply adhere to fabrics, enhancing the durability of printed designs. This technology ensures that the prints remain vibrant and withstand multiple washes, making them ideal for high-use apparel.

How do DTF transfers contribute to cost-efficiency in printing?

DTF transfers contribute to cost-efficiency by allowing businesses to print multiple designs on a single gang sheet, minimizing ink and material waste. This approach significantly lowers production costs, making DTF a financially viable option for custom printing.

Why is quick turnaround a significant advantage of DTF technology for custom printing?

Quick turnaround is a significant advantage of DTF technology as it allows businesses to print on demand and respond rapidly to customer requests and last-minute orders. This enhances customer satisfaction and can provide a competitive edge in the fast-paced custom apparel market.

In what ways does DTF printing appeal to larger retailers?

DTF printing appeals to larger retailers by accommodating bulk custom orders and offering personalization options that cater to diverse consumer needs. Companies leveraging DTF technology can efficiently handle significant quantities of transfers daily, attracting both individual clients and large trade accounts.

| Key Point | Details |

|---|---|

| What Are DTF Transfers? | DTF (Direct-to-Film) is a printing technique using special film to transfer vibrant designs onto fabrics with heat and pressure. |

| Versatility Across Fabrics | DTF transfers can be used on various materials, including cotton and polyester, allowing vibrant designs on both light and dark fabrics. |

| Cost-Efficiency and Waste Reduction | By utilizing gang sheets and advanced printing technology, DTF minimizes waste and reduces costs, especially beneficial for small businesses. |

| High Quality and Durability | DTF transfers provide excellent print quality that withstands multiple washes, ensuring longevity and customer satisfaction. |

| Quick Turnaround Times | DTF allows quick production and on-demand printing, enhancing service delivery and customer satisfaction. |

| Broader Market Appeal | DTF’s adaptability to various consumer needs attracts both individual customers and larger retailers, expanding market opportunities. |

Summary

DTF transfers are revolutionizing the custom apparel industry by offering an array of advantages that elevate design potential. From their impressive versatility on different fabrics to their cost-effective printing processes, DTF transfers provide unmatched quality and durability while ensuring quick turnaround times. This innovative printing technique is not only appealing to individual consumers but also caters to large-scale retailers, making it a strategic tool for businesses aiming to thrive in a competitive market. With the increasing demand for personalized and unique designs, integrating DTF transfers into production is essential for success in the ever-evolving fashion landscape.