The DTF printing process, or Direct to Film printing, is transforming the landscape of custom apparel printing with its innovative and efficient method of design transfer. Unlike traditional fabric printing techniques, DTF technology utilizes a specialized film and vibrant inks that allow for intricate designs to be applied to various fabric types seamlessly. This modern approach not only enhances the color quality and detail of prints but also caters to the burgeoning demand for personalized apparel in today’s fast-paced market. In this blog post, we will delve deep into the advantages of DTF printing and how this cutting-edge technique is reshaping the industry, making it easier for businesses to adapt to consumer needs. Join us as we explore the dynamic world of DTF printing, revealing its significance as a leading fabric printing technique.

In recent years, the landscape of textile design has been dramatically impacted by emerging methods such as Direct to Film printing, often referred to as DTF printing. This fabric printing technique stands out for its unique ability to produce high-quality artwork directly onto a special film before transferring it to a variety of materials. The efficiency of DTF printing technology allows for cost-effective custom apparel solutions, offering distinct advantages over traditional methods like screen printing and heat transfer. As the demand for custom designs increases, many businesses are turning to DTF for its advancements in print durability and vibrancy. Join us as we uncover the essentials of this revolutionary printing strategy and why it’s gaining traction in the world of fashion.

The Basics of Direct to Film Printing

Direct to Film (DTF) printing has revolutionized the way custom apparel is created, merging traditional printing techniques with modern technology. This innovative approach allows designers to produce detailed and vibrant prints with relative ease. Unlike traditional Direct to Garment (DTG) methods that require specific types of fabric, DTF printing is versatile and works on various material types including cotton, polyester, and blends. This flexibility accounts for DTF printing’s growing popularity among custom apparel manufacturers looking to cater to a diverse clientele.

The DTF printing process is incredibly user-friendly, beginning with the design phase. Designers can utilize advanced graphic design software to create high-resolution images that are then printed onto specialized film. This aspect not only enhances creativity but also allows for efficient production cycles, enabling businesses to quickly adapt their offerings to meet ever-changing fashion trends. By removing complex setup requirements, DTF makes it feasible for small businesses to enter the custom printing market without significant upfront investments.

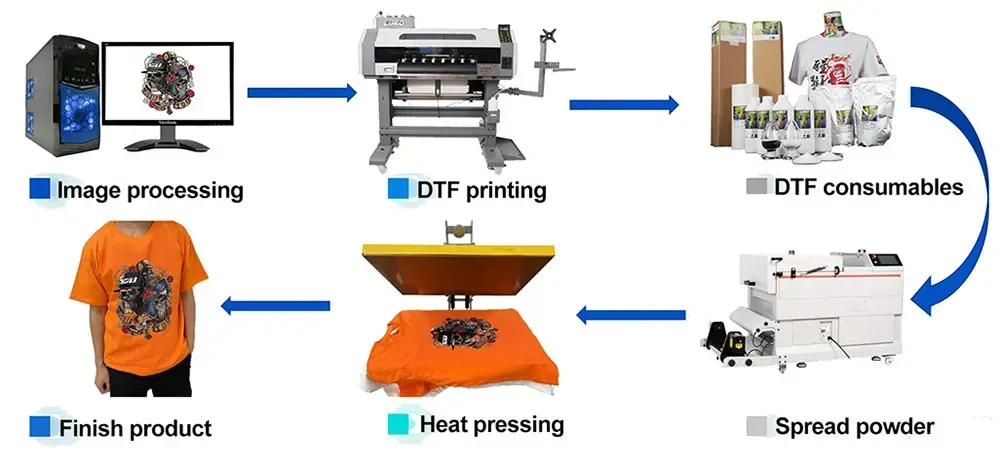

Key Stages in the DTF Printing Process

Understanding the step-by-step approach of the DTF printing process is essential for harnessing its full potential. The initial stage involves creating a unique design that is printed onto a transfer film using specially formulated DTF inks. This stage is crucial as the quality of the ink determines the vibrancy and durability of the final print. Following this, an adhesive powder is applied while the design is still wet, which will bond with the fabric during the heat transfer phase.

Post-printing, the film undergoes a curing process where heat is applied to activate the adhesive powder. This ensures that the design is strongly bonded with the film before it is placed onto the clothing material. Once aligned, the design is applied to the fabric using a heat press, a critical moment that locks in the vibrant colors and details of the print. With DTF, the final peeling stage reveals a stunning result, showcasing colors and sharp detail comparable to traditional methods like screen printing.

Benefits of Using DTF Printing for Custom Apparel

One of the most compelling advantages of DTF printing is its versatility. This technique allows for high-quality prints on a wide range of fabrics, including both natural fibers like cotton and synthetic blends like polyester, minimizing limitations often seen with conventional printing methods. Businesses can now offer personalized garments that appeal to various consumer preferences, from casual wear to performance apparel.

Another notable benefit is the cost-effectiveness of producing smaller runs of apparel. DTF printing eliminates many of the initial setup costs associated with methods like screen printing. This feature is particularly advantageous for startups and small businesses that want to test their designs in the market without incurring heavy financial risks. The ability to produce custom designs on demand paves the way for a more dynamic business model tailored to contemporary consumer demands.

Recent Innovations in DTF Printing Technology

DTF printing has undergone remarkable technological advancements in recent years, enhancing its suitability for a broader range of applications in custom apparel. New ink formulations have been developed to not only improve print quality but also the wash durability of designs. Such innovations ensure that prints remain vibrant even after repeated washing, addressing one of the primary concerns for consumers and apparel manufacturers alike.

Moreover, user-friendly DTF printing systems have emerged, making it increasingly accessible for small and medium-sized enterprises. As providers refine these setups, they empower more businesses to leverage DTF technology without the need for substantial technical expertise, allowing them to compete effectively in the fast-evolving world of fashion and custom printing.

Industry Trends Impacting DTF Printing Adoption

The rise in demand for personalized apparel has significantly impacted the adoption of DTF printing within the industry. As consumers increasingly seek unique, custom-designed garments, manufacturers are turning to efficient printing methods like DTF to fulfill these needs. In particular, the ease of modifying designs quickly allows apparel makers to keep pace with the ever-changing trends in fashion.

Industry analysts predict that by 2025, a substantial number of small and medium enterprises will incorporate DTF printing into their production processes. This trend reflects a shift towards more agile manufacturing practices and a desire for high-quality finishes at speed, emphasizing the importance of adaptability in meeting consumer demands.

Conclusion: The Future of Custom Apparel with DTF Printing

As the landscape of custom apparel continues to evolve, DTF printing presents an invaluable tool for manufacturers seeking to maintain a competitive edge. Its unique combination of versatility, speed, and vibrancy positions it as a preferred choice among businesses aiming to innovate in the fashion market. Understanding the nuances of the DTF printing process is crucial for entrepreneurs looking to navigate this dynamic sector successfully.

By embracing the DTF printing technology and its benefits, businesses can not only enhance their product offerings but also tap into a burgeoning market trend towards customized products. By continuously investing in this printing technique, apparel producers can ensure that they remain relevant, appealing to both fashion-conscious consumers and environmentally conscious shoppers who appreciate quality and sustainability.

Frequently Asked Questions

What is the DTF printing process and how does it work?

The DTF printing process, or Direct to Film printing process, involves printing designs onto a special film using high-quality, water-based DTF inks. This film is then heat transferred onto fabric, creating vibrant and durable designs. The process includes key steps such as design creation, film printing, powder application, curing, and transferring the image to fabric.

What are the main advantages of using DTF printing for custom apparel?

DTF printing offers several advantages: it works well with various fabric types, produces high-resolution colors and details, and is cost-effective for small batch orders. This makes it ideal for custom apparel printing where flexibility and quality are crucial. Additionally, DTF technology allows for unique designs without the significant setup costs of traditional methods.

Can DTF printing be used on different types of fabrics?

Yes, the DTF printing process is highly versatile and suitable for various fabric types, including cotton, polyester, and blends. This ability to adapt to different materials makes DTF printing a popular choice for custom apparel printing across the fashion industry.

How does DTF printing compare to other fabric printing techniques?

DTF printing stands out against traditional methods like screen printing and DTG printing by offering a more cost-effective solution for smaller runs. Additionally, DTF provides high-quality color and detail, enabling complex designs to be achieved with ease and flexibility, which some other techniques struggle with.

What recent innovations have emerged in DTF printing technology?

Recent advancements in DTF printing technology include the introduction of new ink formulations that enhance wash durability and promote eco-friendly practices. These innovations have made DTF systems more user-friendly, allowing even small businesses to adopt the technology easily and compete in the custom printing market.

What impact is DTF printing having on small businesses in the garment industry?

DTF printing is rapidly being adopted by small and medium-sized enterprises due to its affordability and flexibility. Its ability to accommodate low-cost short runs and rapid design adaptation is empowering startups and independent creators, significantly impacting the growth of the custom apparel sector.

| Key Point | Description |

|---|---|

| Overview of DTF Printing | DTF printing combines strengths of traditional methods like DTG and heat transfer, using specialized ink for vibrant, durable designs. |

| Key Steps in the DTF Printing Process | 1. Design Creation 2. Film Printing 3. Powder Application 4. Curing 5. Transfer to Fabric 6. Post-Processing |

| Advantages of DTF Printing | – Versatility on various fabrics – High color and detail quality – Cost-effective for smaller batches |

| Recent Innovations and Trends | Innovations in ink formulation and environmental practices have propelled DTF technology’s adoption in the industry. |

| Industry Insights | DTF printing is rapidly gaining traction with startups and independent creators, providing an accessible solution for custom printing. |

Summary

The DTF printing process has emerged as a transformative method in the realm of custom apparel, offering efficient and versatile solutions for designers and businesses alike. This innovative technique simplifies the task of transferring intricate and vibrant designs onto various fabrics, making it particularly appealing in today’s fast-paced fashion market. By integrating advanced technology and user-friendly practices, the DTF printing process enables even small enterprises to deliver high-quality products without significant upfront costs. As the demand for unique and personalized apparel grows, understanding the DTF printing process becomes essential for anyone looking to succeed in the competitive clothing industry.