DTF Transfers, or Direct-to-Film Transfers, have emerged as a game-changer in the custom apparel printing landscape, offering a fresh and innovative approach to design application. This cutting-edge printing technology allows for high-quality graphics to be transferred onto a variety of fabrics, making it an ideal choice for both small businesses and large-scale production. With distinct advantages such as versatility, vibrant color output, and durability, DTF printing is quickly becoming the preferred option for many entrepreneurs and designers. As market trends show an increasing demand for personalized products, understanding the intricacies of DTF transfers becomes essential for businesses aiming to thrive in the competitive printing sector. In this comprehensive guide, we will delve into the process of DTF printing while exploring the latest printing technology innovations and how they can elevate your production game.

Known as Direct-to-Film printing, DTF transfers deliver unparalleled versatility in the realm of printing technology, allowing for intricate designs to be applied to various textile materials. This advanced method not only simplifies the custom apparel printing process but also enhances the overall quality and durability of finished products. As industry trends lean towards greater personalization and unique designs, more businesses are gravitating towards DTF solutions to meet growing consumer expectations. Evaluating the advantages of DTF transfers can provide insights into how printing capabilities can evolve to keep pace with market demands. In this guide, we will investigate essential aspects of DTF technology, including its benefits and applications.

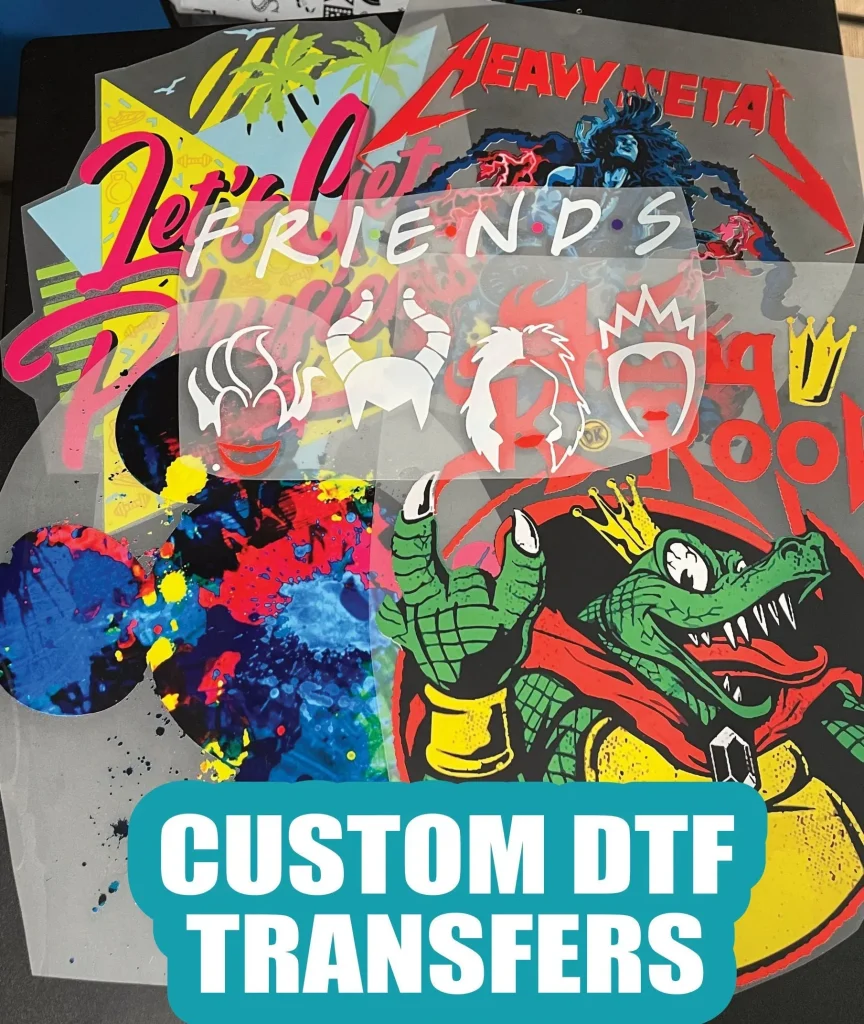

Understanding DTF Transfers: The Future of Printing Technology

DTF transfers, or Direct-to-Film transfers, represent a significant advancement in printing technology, providing a solution for businesses seeking versatility and quality. In contrast to traditional methods, such as screen printing, DTF printing allows for more intricate designs and vivid colors on a wide array of fabrics, making it a preferred choice for custom apparel printing. As this innovative technology continues to evolve, it is poised to transform the landscape of the textile printing industry.

As industries shift towards personalized and custom products, DTF transfers are becoming increasingly relevant. This printing method not only facilitates a broader range of applications but also addresses consumer demand for high-quality prints. By utilizing the latest innovations in printing technology, businesses can enhance their offerings, thereby staying ahead in a competitive market, and tapping into burgeoning trends such as eco-friendly printing solutions.

Why DTF Printing Stands Out: Key Advantages

The advantages of DTF printing are numerous and impactful for businesses looking to upgrade their printing processes. One of the most striking benefits is the adaptability DTF offers in terms of fabric compatibility. Unlike methods bound to specific materials, DTF transfers excel on anything from cotton to polyester, making them ideal for a wide range of applications, including promotional products and personalized gifts.

Additionally, DTF printing provides exceptional durability and quality, producing prints that not only look vibrant but also withstand the test of time. Customers prioritize longevity in printed apparel, leading to repeat business for companies that choose DTF technology. Moreover, the cost-effectiveness of DTF becomes apparent for low-volume orders—reducing overhead costs associated with traditional printing techniques, thereby appealing to small and medium-sized enterprises.

Current Trends in the DTF Printing Market

The DTF printing market is currently experiencing rapid growth, driven by an increasing interest in custom apparel and bespoke products. As e-commerce expands, the demand for personalized printing solutions has surged. Businesses are leveraging DTF technology to meet these demands while also streamlining their operations and improving production timelines. The market trends indicate a robust interest in customization possibilities, making DTF an essential focus for future investment.

Additionally, there has been a noticeable shift towards sustainable printing practices within the DTF landscape. Suppliers and manufacturers are now offering eco-friendly inks and materials that reduce environmental impact, attracting environmentally conscious consumers. This trend speaks volumes about the evolving preferences in the textile industry and positions DTF printing technology as a forward-thinking solution in a market that increasingly values sustainability.

The Role of Technology Innovations in DTF Printing

Technology innovations have played a crucial role in advancing DTF printing capabilities. With improvements in printer resolution and color accuracy, businesses can now produce striking prints that rival traditional methods. Furthermore, advancements in ink formulations and adhesive properties enhance the final product’s quality, allowing for superior adhesion and wash resistance. As these innovations unfold, they redefine the boundaries of what’s possible in custom apparel and textile printing.

Moreover, the accessibility of DTF printing technology has increased significantly, thanks to the introduction of specialized kits designed for various user levels. Hobbyists and professional printers alike can now take advantage of DTF printing without considerable upfront investment. This democratization of technology fosters creativity among entrepreneurs, enabling them to create unique designs and tap into niche markets.

Challenges to Consider When Adopting DTF Technology

While the advantages of DTF printing are compelling, there are several challenges businesses must consider before making the transition. The initial setup costs can be significant due to the equipment required, including high-quality DTF printers and heat presses. Businesses should carefully assess their budget and financing options to ensure they can sustain initial investments before reaping the potential long-term benefits of DTF technology.

Additionally, navigating the learning curve associated with new equipment is vital for successful implementation. Adequate training for staff is necessary to ensure efficient operation and high-quality output. Companies must look into reliable training resources and support systems to facilitate a smooth transition to DTF processes and maximize their new investment.

Maximizing Your Success with DTF Printing

To achieve success with DTF transfers, businesses should focus on sourcing quality materials that complement the printing process. Using high-grade inks and films can significantly affect the final output, ensuring vibrant designs and excellent durability. It’s crucial to establish relationships with reputable suppliers to maintain a consistent quality standard and enhance production reliability.

In addition to quality materials, creativity and design play a vital role in maximizing the potential of DTF printing. To stand out in a crowded market, companies must innovate with their designs and adapt quickly to changing consumer preferences. Utilizing the advantages of DTF technology, such as its versatility for various fabrics, can help businesses tap into diverse markets and broaden their customer base.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct-to-Film Transfers, involve printing designs onto a special film that is then applied to fabrics using heat and pressure. This method allows for vibrant and durable prints on various materials, making it a versatile option for custom apparel printing.

What are the advantages of using DTF printing technology?

DTF printing technology offers several advantages, including versatility in applications, high print quality, and impressive durability. The prints produced are resistant to fading, making them ideal for custom apparel and promotional products.

How does DTF printing compare to traditional printing methods?

Compared to traditional printing methods like screen printing, DTF printing is often more cost-effective for small runs and custom designs. It allows for greater creativity with intricate designs and is not limited by fabric type, providing a broad range of applications.

What are the current market trends for DTF printing?

The DTF printing market is rapidly growing, fueled by the increasing demand for custom apparel and personalized products, particularly in the e-commerce sector. Businesses are increasingly adopting DTF printing technology to stay competitive and meet consumer needs efficiently.

What innovations are emerging in DTF printing technology?

Recent innovations in DTF printing technology include advancements in ink quality and adhesive formulas, enhancing print resolution and durability. Many suppliers are also developing DTF kits tailored for various skill levels, making the technology more accessible.

What should businesses consider before adopting DTF transfers?

Before adopting DTF transfers, businesses should consider initial setup costs for equipment, potential learning curves associated with new technology, and the importance of sourcing high-quality inks and materials to ensure optimal printing results.

| Key Point | Details |

|---|---|

| What is DTF Printing? | DTF printing is a method that prints designs onto a special film, which is then transferred to textiles using heat and pressure. |

| The DTF Process | 1. Printing on Film 2. Applying Adhesive Powder 3. Curing the Adhesive 4. Transferring the Design |

| Advantages of DTF Transfers | 1. Versatility 2. Quality and Durability 3. Cost-Effectiveness |

| Market Trends | Growing demand for custom apparel and e-commerce offerings leads to increased investment in DTF technology. |

| Considerations for Adoption | 1. Initial Setup Costs 2. Learning Curve 3. Sourcing Quality Materials |

Summary

DTF transfers are revolutionizing the textile printing industry by providing businesses with the opportunity to produce high-quality, vibrant designs with ease. This innovative printing technique not only enhances the versatility of fabric applications but also addresses cost-effectiveness for custom design needs. As the demand for personalized products continues to rise, the adoption of DTF transfers can significantly elevate a brand’s offerings and production capabilities. By understanding the DTF process and its benefits, businesses can make informed decisions about investing in this remarkable technology.