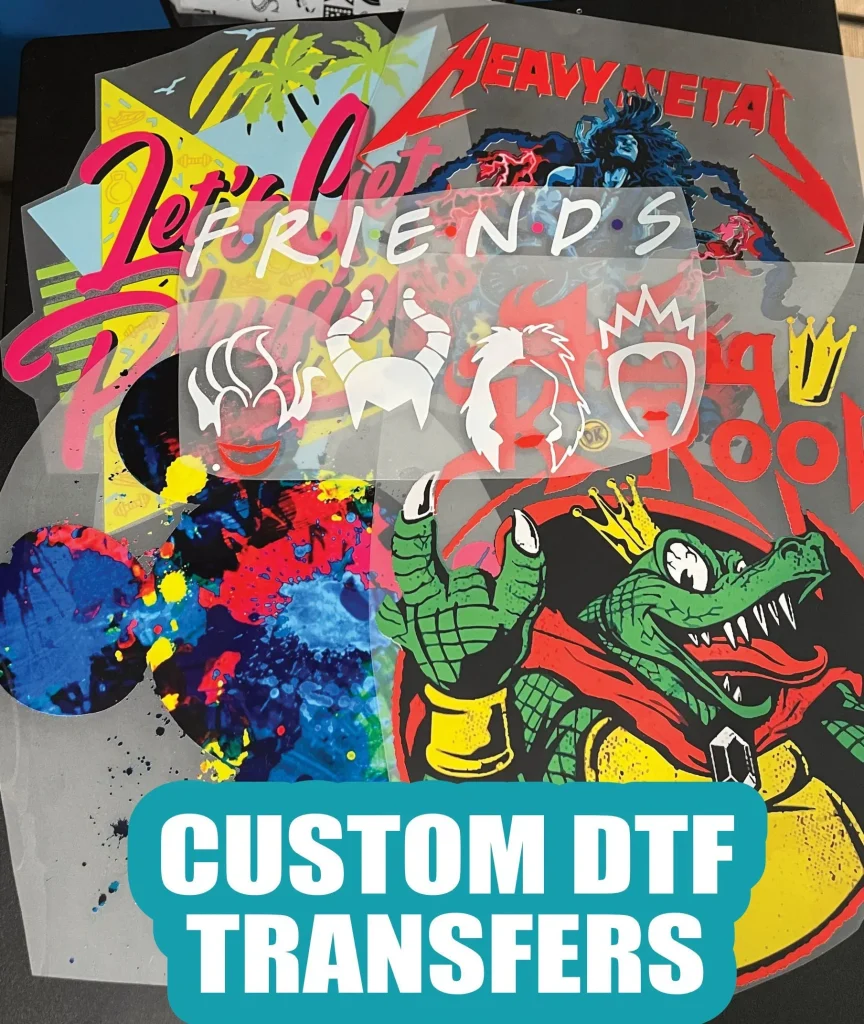

DTF transfers are revolutionizing the way designs are applied to fabric, combining ease of use with exceptional quality. With DTF printing technology, designs are printed on a special DTF transfer paper that can then be heat pressed onto various fabrics, offering vibrant colors and durability. Whether you’re a small business owner or a DIY enthusiast, understanding the best printers for DTF is essential for achieving professional results. The choice of DTF inks and the print quality for DTF transfers can significantly impact the final output, making it imperative to choose wisely. In this guide, we will delve into the vital aspects you need to consider when selecting the right printer for your DTF transfers, ensuring optimal performance for your creative projects.

When it comes to fabric decoration techniques, the world of Direct-to-Film printing offers a blend of practicality and innovation ideal for creators and entrepreneurs alike. Often referred to as DTF printing, this method involves using specialized transfer materials that enable vibrant artwork to be seamlessly applied across a variety of substrates. As the demand for high-quality fabric prints rises, understanding how to select the ideal printer for these applications is crucial for artists and businesses seeking to maximize their output. The success of your printing endeavors hinges on factors such as the quality of transfer films and inks, as well as the chosen printing technology. Navigating these details will equip you with the knowledge needed to excel in the competitive landscape of fabric printing.

Understanding DTF Printing Technology

Direct-to-Film (DTF) printing technology offers a remarkable way to transfer vibrant designs onto various fabrics. Unlike traditional methods, DTF printing utilizes a specialized film that is printed with the design before being heat-pressed onto the desired material. This unique approach not only enhances the durability of prints but also increases the versatility of fabrics on which they can be applied. From cotton to polyester blends, DTF transfers create bright, vivid designs that are long-lasting and resistant to wear.

As DTF printing technology evolves, advancements in both the printing materials and techniques have improved print quality significantly. Innovations in DTF inks and transfer films ensure that the colors remain vibrant after multiple washes, making this process appealing for both personal projects and commercial applications.

Furthermore, the ease of use with DTF printing technology allows both amateurs and professionals to achieve high-quality results without the steep learning curve often associated with other printing methods. Setting up a DTF printer can be relatively straightforward when compared to screen printing or sublimation printing, encouraging more users to explore its possibilities. By understanding the intricacies of DTF technology, one can better appreciate why it has become a favored choice among creatives.

Choosing the Best Printers for DTF

When considering the best printers for DTF transfers, compatibility with DTF technology is paramount. High-resolution inkjet printers are commonly recommended for this printing method due to their ability to handle various inks and produce intricate designs with stunning color accuracy. Models such as the Epson L series or the popular Roland printers have garnered positive feedback for their performance in DTF applications, providing printers that not only support DTF inks but also enhance the overall print quality.

Before making a purchase, it’s advisable to consult various resources for user testimonials and expert reviews. This research will help identify the most reliable models that have proven successful in producing DTF prints, which can save time and resources in the long term. Evaluation of specifications, such as ink delivery systems and print speeds, should also be undertaken to ensure the selected printer meets your volume production needs.

In addition to the specific printer model, considering the printing technology used in these devices can influence the final choice. Look for printers that have been modified for DTF capabilities or those whose manufacturers offer tailored setups for DTF printing. Reviews often highlight not only the print quality achieved but also the cartridge life and print head durability, which can significantly impact your production costs.

Importance of DTF Transfer Paper

DTF transfer paper plays a crucial role in the quality of prints produced during the DTF process. Unlike standard transfer papers, DTF transfer paper is uniquely designed to hold a larger ink volume which enhances the vibrancy and sharpness of colors. Choosing the right type of DTF transfer paper can make a significant difference, impacting everything from adhesion to the longevity of the printed designs on garments. Opting for reputable brands ensures that you are using the best materials available, promoting overall success with your DTF printing projects.

Additionally, the thickness and texture of the DTF transfer paper can influence the final print outcome. While thinner papers might allow for finer details, thicker options may provide stronger adherence when pressed onto fabrics. Understanding these nuances can help users to select the ideal transfer paper that complements their chosen printer and inks, ensuring that the final product meets their desired quality standards.

Furthermore, DTF transfer paper is specifically suited to work effectively with the specialized DTF inks used in the printing process. It offers improved transfer efficiency, ensuring that when adequate heat and pressure are applied, the ink properly bonds with the fabric. This compatibility between inks and paper is essential in producing high-quality, durable prints that can withstand frequent use and washing.

Choosing the Right DTF Inks

Selecting the proper DTF inks is integral to achieving optimal print quality in your DTF transfers. DTF inks are specifically formulated to provide vibrant color output while ensuring good adherence on the DTF transfer paper. The market today offers various types of DTF inks, including water-based and acrylic options, each with specific characteristics that affect print performance. Users should seek inks with high color saturation and durability to withstand washes and everyday wear.

Moreover, DTF inks are vital in determining the end product’s longevity and quality. Inks with high pigment concentration usually yield better color performance and durability, leading to prints that not only look striking but also last longer on fabrics. Therefore, it is beneficial to conduct thorough research on the best DTF inks available, prioritizing well-known brands and user-tested options.

Additionally, it’s essential to consider the ink compatibility with the printer you plan to use. Some printers may perform optimally with specific ink formulations while underperforming with others. Following the manufacturer’s recommendations or seeking advice from experienced users in online communities can help ensure that you choose the right inks tailored to your printer, further enhancing the overall DTF printing experience.

Evaluating Print Quality for DTF Transfers

Print quality is an essential element when considering DTF transfers, as it directly affects the overall appearance of your final product. To achieve stunning prints, it’s critical to evaluate different printers based on their capability to produce high-resolution images with vivid colors. A printer’s DPI (dots per inch) specification plays a significant role here, as higher DPI values translate to more detailed images and smoother gradients in prints. Therefore, selecting a printer with at least 1440 DPI is typically recommended for optimal results in DTF applications.

Moreover, factors such as ink type and transfer paper quality can impact the final print quality as well. Users should ensure that the ink formulation matches the requirements of the transfer paper to achieve great adhesion and durability. This alignment between inks, paper, and printer leads to vibrant and sharp designs, ensuring that the graphics pop and maintain their integrity over time.

Investing time in testing prints on various materials can also help gauge the print quality across different fabric types. Each fabric can absorb inks differently, impacting how colors appear once heat-pressed. Therefore, performing quality checks with sample prints can prevent costly mistakes and ultimately ensure that your DTF transfers consistently meet high standards.

Conducting Thorough User Reviews and Support Research

User reviews and feedback play a significant role in identifying the right printer for your DTF transfers. By examining the experiences of other customers who have utilized specific printer models, you can gain valuable insights into aspects such as usability, print quality, and customer support. Reliable online resources, forums, and social media groups can provide candid reviews that highlight both strengths and weaknesses of various printers in DTF applications.

By engaging with experienced users, you can further validate your choices and make a more informed decision when selecting a printer suited for your DTF printing needs. Awareness of common issues faced by users and how they were resolved can guide you in selecting a model that has robust customer support and well-established troubleshooting resources.

Moreover, understanding the support provided by manufacturers can significantly influence your choice. Top companies often offer warranties, customer service, and extensive documentation related to their printers, which can be invaluable when you come across challenges or require maintenance. Prioritizing printers backed by strong customer support will give you peace of mind and can streamline your operations, ultimately contributing to greater success in your DTF printing endeavors.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct-to-Film Transfers, are a printing method that involves applying ink to a special film, which is then transferred onto fabric using heat and pressure. This DTF printing technology ensures high-quality, durable prints suitable for various materials.

What is the best printer for DTF transfers?

The best printers for DTF transfers are typically modified inkjet printers, particularly models from brands like Epson and Roland. These printers are known for their high-resolution printing capabilities, which enhance color vibrancy and detail in your designs.

What type of inks are used for DTF printing?

DTF inks are specialized inks designed for optimal adhesion and print quality on transfer films. Common choices include acrylic and water-based inks, which ensure that the colors adhere well to the substrate during the transfer process.

What factors affect print quality for DTF transfers?

Print quality for DTF transfers is influenced by several factors, including the printer’s DPI (dots per inch), the type of DTF transfer paper used, and the quality of inks. Printers with a minimum resolution of 1440 DPI are recommended for sharp and vibrant prints.

How do I choose the right DTF transfer paper?

Choosing the right DTF transfer paper involves considering factors such as compatibility with your printer, the desired finish (matte or gloss), and the weight of the paper. Using high-quality DTF transfer paper is essential for achieving the best print results.

What are the cost considerations for DTF printing?

When evaluating DTF printing costs, consider the initial investment in the printer, the ongoing costs of DTF inks, transfer paper, and maintenance. Some printers may have higher upfront costs but can provide long-term savings through lower ink consumption and durability.

| Key Consideration | Details |

|---|---|

| Printer Type | Inkjet printers are recommended, especially modified Epson and Roland models. |

| Ink Type | Use specialty inks like acrylic or water-based for optimal results. |

| Print Resolution | A minimum resolution of 1440 DPI is recommended for sharp prints. |

| Size and Format | Ensure compatibility with various DTF transfer paper sizes. |

| Cost Efficiency | Consider total ownership costs, not just the purchase price. |

| User Reviews and Support | Research reviews for insights on performance and reliability. |

| Additional Features | Look for integration with design software and user-friendly controls. |

Summary

DTF Transfers represent a revolutionary method in the textile printing industry, enabling creators to produce high-quality prints with ease. Selecting the right printer for DTF Transfers is crucial, as it directly impacts print quality and production efficiency. By considering factors like printer type, ink compatibility, resolution, and cost-efficiency, users can streamline their operations and achieve exceptional results. In a landscape where innovation continues to reshape the way transfers are executed, staying informed about the latest technologies and models ensures that both hobbyists and professionals can leverage the full potential of DTF Transfers.