The UV DTF process, or UV Direct-to-Film, is transforming the landscape of custom printing by providing innovative solutions that cater to diverse consumer needs. This cutting-edge technology combines conventional printing techniques with the advancements of UV printing technology, resulting in high-definition prints that are both vibrant and durable. Businesses can leverage the UV DTF process to create customized products that stand out in today’s competitive market. With a focus on sustainable printing practices, this method not only meets the increasing demand for quality but also aligns with environmental considerations. As we delve into the nuances of the UV DTF process, you’ll discover how it is reshaping the future of printing and offering exciting opportunities for marketers and manufacturers alike.

Revolutionizing the custom printing industry, the UV Direct-to-Film technique, often abbreviated as UV DTF, utilizes innovative methodologies that merge traditional and modern printing processes. This method leverages UV light to cure inks on various substrates, producing stunning prints that are ideal for a myriad of applications, from promotional materials to personalized merchandise. As an integral part of this evolution, UV printing technology emphasizes efficiency and sustainability, appealing to businesses aiming for responsible production practices. Furthermore, the rise of custom printing solutions tailored to individual requirements signifies a shift towards a more customer-centric market. Embracing the power of UV DTF is a strategic move for businesses looking to enhance their product offerings while minimizing their environmental impact.

The Evolution of Custom Printing Technologies

The landscape of custom printing has undergone significant transformations over the past few decades. New technologies such as UV printing technology have introduced creative possibilities, allowing businesses to innovate and engage with their customers in unprecedented ways. These advancements not only enhance aesthetic appeals through vibrant colors and intricate designs, but they also increase production efficiency, paving the way for timely deliveries and customer satisfaction.

In particular, the introduction of the UV Direct-to-Film (UV DTF) process stands out as a game-changer in this competitive industry. By combining innovative curing techniques with traditional printing methods, businesses are now equipped to offer a myriad of customized products that meet various niche demands. As such, understanding these evolutions in printing technology is vital for businesses aiming to stay relevant and competitive.

Understanding the UV DTF Process

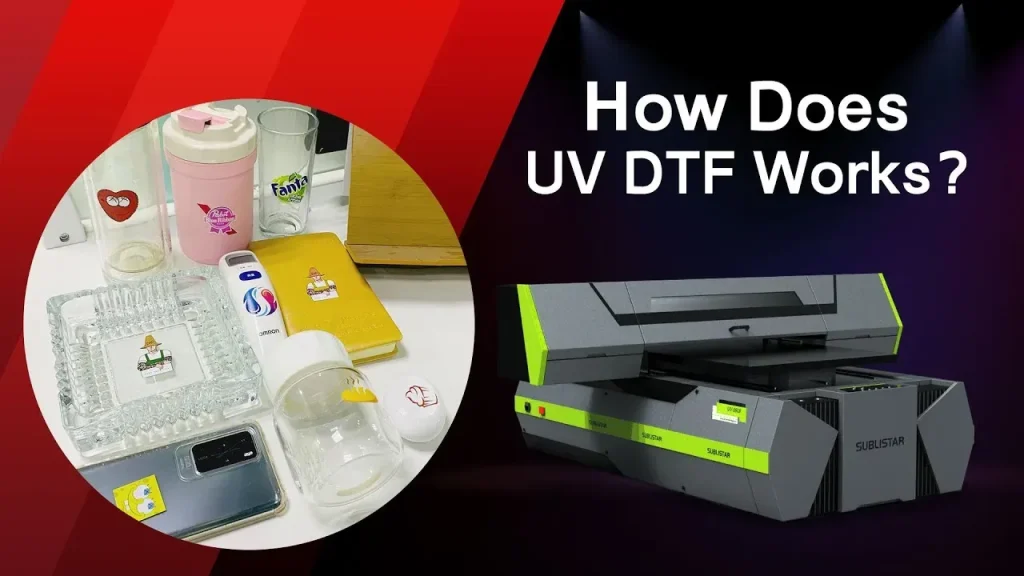

At the heart of modern custom printing lies the UV DTF process, which brilliantly merges the principles of direct-to-garment technology with the power of UV light for curing inks. This method impressively broadens the horizons for printers by allowing designs to be transferred effectively onto numerous materials, thereby significantly diversifying product offerings. Not only does this versatility increase creativity, but it also helps businesses to cater to a wider array of client requests and preferences.

The unique curing mechanism employed in the UV DTF process ensures immediate drying of inks, resulting in high-quality prints that are vibrant and highly detailed. This emphasizes the importance of mastering the UV DTF technology, as it allows businesses to provide superior-quality customized products that are demanding in today’s marketplace. Such capabilities can significantly enhance a company’s reputation and lead to repeat customers.

Advantages of Using UV DTF Printing

One of the most compelling advantages of the UV DTF process is its incredible versatility. Businesses can apply UV DTF to a broad spectrum of substrates, including textiles, wood, and metal, which empowers them to fulfill a variety of specialized custom printing requests. This characteristic alone can transform a company’s operational model, enabling them to readily introduce new product lines tailored to customer desires.

Moreover, the durability of prints produced through the UV DTF process cannot be overstated. By utilizing UV light for curing, the inks are rendered scratch-resistant and long-lasting, which is particularly crucial for items such as promotional products and apparel that face regular use. In an era where consumers prioritize quality and longevity, the reliability of UV DTF prints fosters trust and customer loyalty, ensuring businesses can thrive in a competitive environment.

Sustainable Practices in UV DTF Printing

Sustainability is a pressing concern in today’s manufacturing landscape, and the UV DTF process contributes significantly to eco-friendly practices. By minimizing chemical usage and reducing waste, the process aligns with global efforts to promote sustainable printing technologies. This not only reflects positively on the company’s brand image but also appeals to environmentally conscious consumers who prioritize sustainability in their purchasing decisions.

As technologies evolve, it’s imperative for businesses to embrace sustainable techniques if they want to succeed long-term. Adopting processes such as UV DTF not only enhances operational efficiency but also positions a company as a leader in environmentally friendly practices. This commitment to sustainability is increasingly becoming a deciding factor for consumers, making it a strategic advantage in the custom printing marketplace.

Impact of UV DTF on the Printing Market

The impact of UV DTF on the custom printing market has been profound, revolutionizing the ways businesses engage with their customers. With the ability to produce high-quality, vibrant prints quickly, the technology enables businesses to respond to market demands with agility. In a world where consumers increasingly seek personalized products, this capability allows companies to stand out in a saturated market.

Additionally, the growing adoption of UV DTF among small and medium-sized enterprises (SMEs) signifies its beneficial influence on market competition. By lowering the barrier to entry in terms of setup costs and operational complexity, UV DTF empowers these businesses to offer customized products efficiently, thereby driving innovation and customer satisfaction across the industry.

Future Trends in UV DTF Technology

As the custom printing industry continues to advance, so too do the capabilities within the UV DTF process. Emerging trends suggest that improvements in ink formulations and printer technology will further amplify the quality of prints. Industries are witnessing innovations that promise broader color gamuts and enhanced adhesion, which could expand design possibilities even more.

Furthermore, the emphasis on sustainability will continue to shape the future of UV DTF technology. As manufacturers seek to reduce their environmental footprint, advancements will likely focus on eco-friendly inks and materials. Keeping pace with these trends is essential for businesses aiming to ensure that their printing solutions not only meet quality standards but also align with consumers’ growing environmental consciousness.

Frequently Asked Questions

What is the UV DTF process in custom printing?

The UV DTF (UV Direct-to-Film) process combines the advantages of direct-to-garment printing and UV printing technology. It allows for vibrant designs to be printed on various substrates, including textiles and plastics, using UV light to cure inks instantaneously, resulting in high-quality, durable prints.

What are the advantages of using UV DTF technology for custom printing?

UV DTF offers several compelling advantages: versatility in printing on multiple materials, exceptional durability resistant to scratches and fading, fast production times due to simultaneous printing and curing, and environmentally friendly practices by reducing waste and chemical use.

How does the UV DTF printing process work step-by-step?

The UV DTF process involves several key stages: 1) Design creation using graphic software, 2) Printing the design onto a specialized film with UV inks, 3) Curing the ink with UV light for immediate adhesion, and 4) Transferring the design to the final substrate using a heat press.

Is UV DTF a sustainable printing option?

Yes, the UV DTF process is considered a sustainable printing option. It uses fewer resources and produces less waste compared to traditional printing methods. Its eco-friendly nature aligns with the industry’s growing emphasis on sustainable printing practices, appealing to environmentally conscious consumers.

What types of products can be created using UV DTF printing?

The UV DTF process allows for the creation of a wide range of customized products, including apparel, promotional items, and decorative goods. Its versatility in printing on various substrates enables businesses to cater to diverse customer needs effectively.

How has UV DTF technology impacted the custom printing market?

UV DTF technology has significantly impacted the custom printing market by increasing product variety and enhancing print durability, which fosters customer loyalty. Its rapid production capabilities also meet the demands for quick turnaround times, helping businesses remain competitive.

| Key Points | Description |

|---|---|

| What is UV DTF? | A printing method that utilizes UV light to cure inks on various surfaces, allowing for vibrant and detailed designs. |

| Advantages | 1. Versatility: Works on multiple materials. 2. Durability: Prints resist scratches and fading. 3. Fast Production: Quick processing and turnaround times. 4. Reduced Waste: Eco-friendlier, using fewer resources. |

| The UV DTF Process | 1. Design Creation: Artwork is digitally created. 2. Printing: Designs are printed onto a specialized film. 3. Curing: UV lights cure inks almost instantly. 4. Transfer: The design is applied to the substrate. |

| Recent Developments | Innovations in ink formulations and printer technologies, along with a focus on sustainability, are driving mainstream adoption of UV DTF. |

| Market Impact | Enhances product variety, fosters customer loyalty through durability, and meets consumer demand for fast production. |

Summary

The UV DTF process is a groundbreaking approach in the custom printing industry, seamlessly blending technology and art to deliver unique, high-quality products. This process, characterized by its versatility across various materials, exceptional durability, and rapid production capabilities, is redefining how businesses cater to diverse consumer needs. As sustainability continues to shape market trends, the UV DTF process stands out not only for its innovative technique but also for its reduced environmental impact. Companies adopting this technology can look forward to enhanced customer satisfaction and loyalty, leveraging quick turnaround times and superior product offerings to thrive in a competitive landscape. Embracing the UV DTF process thus not only enhances production efficiency but also positions businesses favorably amid evolving industry dynamics.