If you’re exploring the dynamic realm of garment printing, you’ve likely come across **DTF printing**, a revolutionary method that’s reshaping the landscape of custom apparel. Short for Direct to Film printing, this innovative technique marries exceptional image quality with unparalleled versatility, making it a favorite among designers and businesses alike. In this guide, we will delve into everything you need to know about the DTF process, including its benefits, necessary equipment, and operational steps. Whether you’re launching a new clothing line or seeking unique creations for personal use, this exploration of DTF printing will provide the insights required to embark on your journey. With DTF printing advantages such as high-quality results and cost-efficiency, it’s no wonder this technology is gaining momentum in the industry.

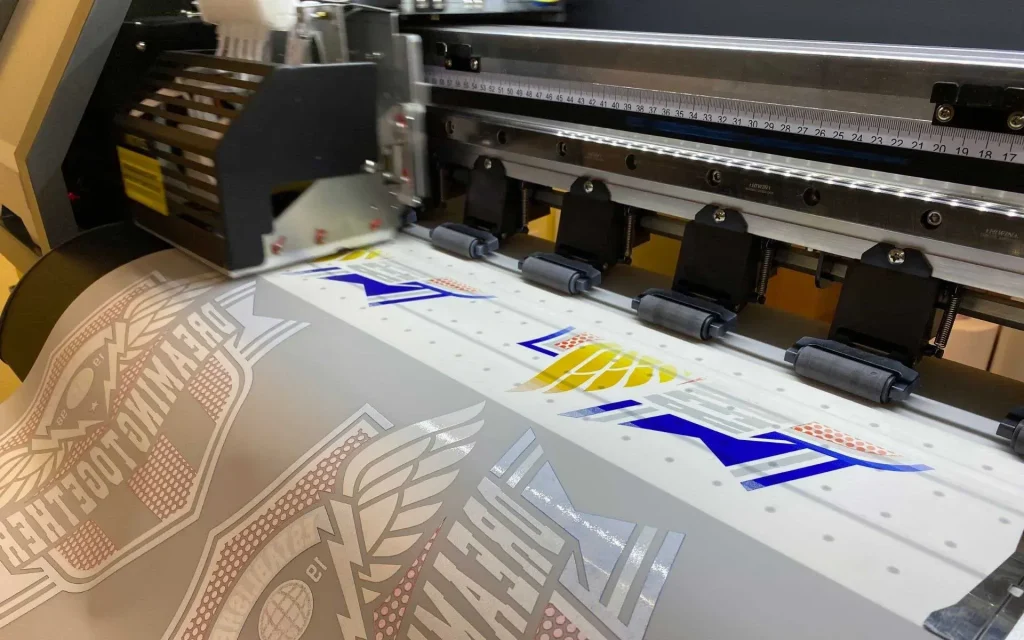

In the ever-evolving world of textile decoration, many enthusiasts are turning to the **Direct to Film** method, often referred to colloquially as DTF printing. This cutting-edge printing process utilizes a special film to create vibrant, detailed designs that can be transferred seamlessly onto various fabrics. Through the use of innovative **DTF equipment**, enthusiasts and businesses can achieve professional-grade results that rival conventional printing methods. The appeal of this approach lies in its adaptability for **custom apparel** and its ability to produce eye-catching graphics with remarkable clarity. As we explore the nuances of this technique, we’ll uncover why the DTF process is swiftly becoming a preferred choice for modern garment printing ventures.

Understanding the DTF Process

The Direct to Film (DTF) process is a revolutionary advancement in the realm of textile printing, enabling designers to seamlessly transfer intricate designs onto fabric. Unlike traditional printing methods, DTF utilizes a specialized film that serves as the medium for transferring high-quality images. This process involves initially printing your design onto the film with DTF inks specifically formulated for vibrant and durable results. Once printed, a hot melt adhesive powder is sprinkled over the wet ink, forming a bond that will later adhere to the fabric during the heat pressing stage.

This unique approach not only enhances the vibrancy and detail of the printed images but also allows for a wider range of fabric compatibility. Whether you are working with cotton, polyester, or various blends, the DTF process ensures that your designs maintain their quality and clarity after washing. This versatility makes DTF printing an ideal choice for custom apparel creators looking to deliver high-quality products that stand out in today’s competitive market.

The Advantages of DTF Printing

DTF printing boasts several noteworthy advantages that make it increasingly favored among custom apparel specialists. Firstly, its versatility allows for applications across various textiles, accommodating an array of materials from t-shirts to hoodies, thereby broadening the scope of potential designs and products. Additionally, the high resolution of DTF prints means that intricate patterns and vibrant colors can be effectively captured, resulting in visually stunning pieces.

Cost-effectiveness is another significant advantage, as DTF printing allows businesses to print on demand. This means that they can cater to specific orders without the need for bulk pre-sales, minimizing waste and optimizing resources. This method is particularly beneficial for small businesses or those looking to cater to niche markets, providing an efficient and sustainable printing solution that meets the demands of modern consumers.

Essential DTF Equipment for Beginners

Embarking on the journey of DTF printing requires investing in the right equipment to ensure high-quality results. Key components include a specialized DTF printer designed for high-fidelity inks, which is pivotal in achieving true-color representation in your printed designs. Alongside the printer, DTF adhesive powder is essential for ensuring a robust bond between the printed film and the fabric, contributing to the longevity of the garment.

Moreover, a reliable heat press is vital in the DTF process, as it applies the necessary heat and pressure for successful transfer. Beginners may benefit from investing in a DTF starter kit, which often includes all necessary components, making it easier to kickstart a custom apparel business with minimal hassle. Familiarizing yourself with this basic equipment not only sets the foundation for your printing endeavors but also enhances your ability to experiment and innovate within this exciting craft.

Step-by-Step Guide to DTF Printing

Understanding the step-by-step process of DTF printing is crucial for beginners seeking to create custom apparel efficiently. The journey begins with designing your artwork using graphic design software, ensuring that your files are high-resolution and colorful. Once your design is finalized, it’s printed onto the transfer film using your DTF printer, followed by immediate application of the hot melt adhesive powder to the wet ink. This step is vital for achieving a strong bond during the heat transfer process.

After preparing your printed design, place it onto your chosen fabric and secure it in place using a heat press. The heat and pressure applied during this step will effectively transfer your design onto the garment, resulting in a high-quality finish. After allowing time for cooling, carefully peel away the film backing to reveal your vibrant custom print. Following this guide ensures that your DTF projects not only fulfill client expectations but also embody the quality and detail that the DTF method promises.

Exploring Market Trends in DTF Printing

The DTF printing market is experiencing significant growth, with emerging trends indicating a shift towards sustainability and customization. As more businesses adopt DTF technology, they are benefiting from reduced setup costs, which makes it accessible for small to medium enterprises looking to capitalize on bespoke garment printing. Furthermore, the expansion of DTF ink and film options allows for even greater creativity and personalization, enabling designers to cater to a wide variety of consumer preferences.

Moreover, as the industry evolves, there is a noticeable trend towards eco-friendly practices within DTF printing. With its ability to reduce ink waste and promote on-demand printing, DTF technology aligns well with the growing consumer demand for sustainable products. This convergence of sustainability and high-quality output makes DTF printing a competitive choice, setting a new standard in the custom apparel sector that appeals to an environmentally-conscious audience.

Getting Started with DTF Printing: Tips for Success

Entering the world of DTF printing can initially seem daunting, but with the right preparations, anyone can excel. For newcomers, starting with a DTF starter kit is a wise choice, as it typically includes all essential components—printer, inks, and films—tailored for efficient setup. Additionally, it’s beneficial to engage with online communities or forums where you can seek advice, share experiences, and learn troubleshooting tips from seasoned DTF users.

As you begin your journey, focus on mastering the fundamentals of design and the printing process. Experiment with different materials and techniques to fully understand the capabilities and limitations of DTF printing. By staying informed about the evolving trends and technological advancements in this field, you can continually enhance your skills and craft unique, high-quality custom apparel that resonates with your audience.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct to Film printing, involves printing a design onto a specialized film. The image is then coated with a hot melt adhesive and transferred to fabric using a heat press. This process ensures vibrant colors and sharp details, making it ideal for custom apparel.

What are the main advantages of DTF printing for custom apparel?

The advantages of DTF printing include its versatility across various materials, high-quality outputs with bright colors and intricate details, and its cost-effective nature due to on-demand printing that minimizes waste.

What equipment do I need to get started with DTF printing?

To start DTF printing, you’ll need a DTF printer compatible with DTF inks, hot melt adhesive powder, and a heat press for transferring the design onto the fabric. These essential tools are crucial for achieving the best results.

Can I use DTF printing on different types of fabrics?

Yes, DTF printing is highly versatile and can be applied to a variety of fabrics, including cotton, polyester, and their blends. This flexibility allows for diverse custom apparel options.

Is DTF printing cost-effective for small batches of custom designs?

Absolutely! DTF printing is particularly cost-effective for small runs or bespoke orders since it allows for on-demand printing, reducing material waste and ensuring you only produce what you need.

What resources are available for learning DTF printing techniques?

Beginners can benefit from DTF starter kits that include essential equipment and access online resources like tutorials, community forums, and tips from experienced users to master the DTF process efficiently.

| Topic | Description |

|---|---|

| What is DTF Printing? | A method of transferring designs onto textiles by printing on specialized film, applying adhesive, and using a heat press to transfer the design. |

| Advantages | 1. Versatility for various materials 2. High quality with vibrant colors 3. Cost-effective with reduced waste through on-demand printing |

| Necessary Equipment | – DTF Printer – Hot melt adhesive powder – Heat press |

| Step-by-Step Process | 1. Design Creation 2. Printing the Design 3. Applying Adhesive 4. Transfer to Fabric 5. Peeling the Film |

| Getting Started | Begin with a DTF starter kit that includes necessary tools and resources. Utilize online tutorials and communities for support. |

| Market Trends | Ongoing advancements in DTF printing improving quality and cost, making it favorable for SMEs, with a focus on sustainability and customization. |

Summary

DTF printing is revolutionizing the garment printing industry, seamlessly combining quality and efficiency. Understanding the key components of Direct to Film printing, including its process, equipment, and advantages, is crucial for anyone looking to thrive in this field. Whether you’re starting a business or just interested in custom designs, DTF printing offers a unique and versatile solution that caters to diverse material requirements and design needs. The ongoing trends in the DTF market also indicate a promising future for this technique in terms of sustainability and innovation, making it an ideal choice for both novices and seasoned professionals alike.