The DTF Gangsheet Builder stands at the forefront of modern printing technology, revolutionizing the DTF printing process for professionals across the industry. As Direct to Film (DTF) printing gains popularity for its ability to create stunning designs, mastering the use of a Gangsheet Builder becomes key in optimizing workflow and material usage. This innovative tool enables users to combine multiple designs into a single sheet, significantly enhancing efficiency and reducing costs. In this guide, we will share essential DTF printing tips, delve into gangsheet optimization strategies, and provide insights on heat press settings for DTF success. Whether you’re just starting or looking to refine your skills, the DTF Gangsheet Builder is your gateway to achieving high-quality prints with minimal waste.

When diving into the realm of Direct to Film printing, understanding the essentials of your DTF Gangsheet Builder is crucial for maximizing its effectiveness. This advanced tool allows users to efficiently batch multiple images onto one film sheet, paving the way for streamlined production and optimal usage of resources. By leveraging effective printing layout techniques and selecting appropriate heat press settings, professionals can elevate their output quality. Moreover, incorporating DTF adhesive powder correctly ensures that each design adheres perfectly to the fabric. In this article, we aim to equip you with valuable insights for navigating the intricacies of DTF printing, ensuring you produce vibrant and durable prints every time.

Essential DTF Printing Tips for Professionals

When venturing into DTF printing, it is paramount for professionals to familiarize themselves with essential printing tips. One key recommendation is to always use high-quality inks that are compatible with your DTF printer. Quality inks not only produce vibrant colors but also ensure durability and longevity in your final products. Additionally, testing various print settings and materials on scrap pieces before executing a full order allows for optimizing results and minimizing waste.

Another critical tip for DTF printing is mastering the art of color correction. DTF printers operate best with RGB color profiles, so always ensure your designs are compatible with this format. Engaging in routine color calibration of your printer will maintain consistent vibrancy across all prints. Moreover, maintaining a clean environment helps prevent contaminants from affecting the print quality.

Maximizing Efficiency with DTF Gangsheet Builder

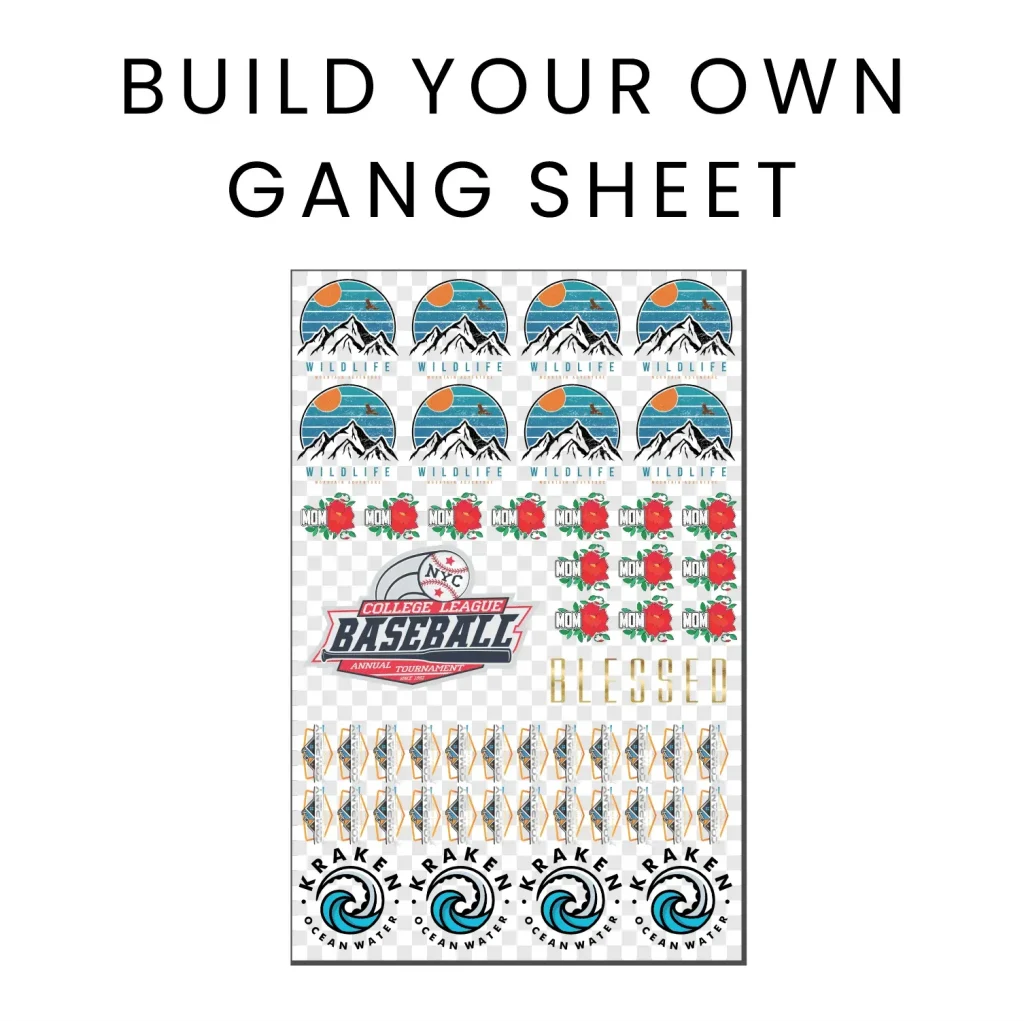

Using a DTF Gangsheet Builder significantly enhances the efficiency of your printing process. Instead of printing designs individually, combining multiple designs into one gang sheet reduces film waste and speeds up the overall workflow. Professionals can achieve higher productivity levels, enabling them to take on more orders without compromising quality.

Moreover, optimizing the layout in your Gangsheet Builder is essential. Consider factors like image size and spacing—using the builder’s grid can help arrange designs effectively to make the most out of each print run. Always take into account the cutting margins to ensure precision in the final products, allowing for a seamless transition from printing to final application.

Mastering DTF Heat Press Settings

Understanding the intricacies of heat press settings is vital for successful DTF printing transfers. Manufacturers provide specific temperature guidelines for each type of DTF film, which should be closely followed to avoid issues such as adhesion failures or substrate damage. An ideal starting point for most DTF films is usually around 320°F, but always refer to your specific film’s instructions for accuracy.

Similarly, pressure settings play a critical role in the transfer process. Too little pressure can result in incomplete transfers, while too much can lead to over-saturation and unwanted marks. A good practice is to perform test presses with varying pressure settings to find the sweet spot that guarantees a clean and vibrant transfer.

Selecting Quality Materials for DTF Printing

The selection of materials is crucial for achieving stunning DTF prints. High-quality films and inks are non-negotiable; they directly affect the adhesion and durability of the final product. When sourcing DTF films, consider characteristics such as opacity and flexibility, ensuring they align with your fabric types for optimum results.

In addition to films, the choice of adhesive powder cannot be overlooked. Using the right type and ensuring you apply the correct quantity is essential. Too little adhesive can lead to peeling designs, while excessive amounts may create a messy residue. Identifying the right adhesive powder for each specific job can significantly improve the quality of your prints.

The Importance of Conducting Test Prints

Test prints are an indispensable part of the DTF printing process. Before launching into larger production runs, executing test prints allows professionals to tweak color settings, validate print layouts, and make any necessary adjustments without incurring significant material costs. Using scrap fabrics for these initial tests can help identify potential issues early on.

Moreover, incorporating a variety of fabric samples during test runs is beneficial. Different substrates may respond uniquely to DTF processes; thus, testing on diverse materials can help secure optimal results across your product range. Engaging in this practice not only optimizes quality but also builds confidence in your print settings.

Engaging with the DTF Community for Growth

Networking within the DTF printing community is an excellent way to enhance your skills and knowledge. By joining forums, attending seminars, and participating in local workshops, professionals can share valuable insights, gain new perspectives on common challenges, and learn about the latest trends and technologies in the industry.

Collaboration often leads to discovering innovative techniques and solutions that can improve your DTF printing processes. Engaging with fellow professionals provides opportunities to discuss everything from printing layouts to equipment maintenance, ensuring that all members of the community can continue to grow and adapt within this ever-evolving field.

Frequently Asked Questions

What is a DTF Gangsheet Builder and how does it enhance DTF printing?

A DTF Gangsheet Builder is a tool designed to efficiently arrange multiple designs on a single film sheet for Direct to Film (DTF) printing. By combining designs, it optimizes material usage, reduces waste, and streamlines the printing process, resulting in both cost savings and quicker turnaround times.

How can I optimize my layouts using a DTF Gangsheet Builder?

To optimize layouts with a DTF Gangsheet Builder, arrange your designs as closely as possible while maintaining sufficient margins for cutting. Utilizing design software can aid in visualizing the layout, allowing for adjustments that minimize wasted film and enhance cost-effectiveness.

What are important heat press settings for successful DTF printing?

For successful DTF printing, it’s crucial to set the correct temperature and pressure on your heat press. Follow the film manufacturer’s guidelines for optimal temperature—overheating can damage the substrate, while too low may hinder adhesion. Ensure even pressure coverage for effective transfers.

What are some DTF printing tips for selecting the right adhesive powder?

When selecting DTF adhesive powder, choose quality types compatible with your prints. The quantity used is important; too little can cause peeling, and too much can leave residue. Experiment with different amounts to find the ideal balance, ensuring strong adhesion and clean finishes.

What are effective printing layout techniques using DTF Gangsheet Builder?

Effective printing layout techniques with a DTF Gangsheet Builder include utilizing high-resolution images for clarity, converting files to RGB color profiles for vibrant results, and arranging designs efficiently to maximize material use. Regular testing of layouts on scrap fabric can help perfect your approach.

How can I ensure regular maintenance of my DTF printing equipment?

Regular maintenance of your DTF printing equipment includes cleaning your printer to prevent clogs, conducting routine checks, and keeping your software updated. This helps maintain print integrity and ensures your DTF Gangsheet Builder operates effectively, minimizing defects during production.

| Key Aspect | Details |

|---|---|

| Understanding DTF Technology | DTF printing transfers designs from film to fabric using heat press and adhesive powder, allowing intricate designs and vibrant colors. |

| Benefits of Using a DTF Gangsheet Builder | Cost efficiency, time-saving, and quality control through optimized material usage. |

| Creating Efficient Gang Sheets | Optimize layouts, use high-res images, prepare files in RGB color profile to reduce waste and ensure quality. |

| Selecting the Right Materials | Focus on high-quality films, inks, and appropriate adhesive powder amounts for durability and vibrancy. |

| Conducting Tests Before Large Runs | Always perform test prints on scrap fabrics to optimize printer settings. |

| Heat Press Settings | Adjust temperature and pressure settings appropriate to the DTF film for optimal adherence. |

| Regular Maintenance | Maintain printers and regularly update software to prevent issues. |

| Engaging with the DTF Community | Network with peers to learn and share experiences and techniques for printing. |

Summary

The DTF Gangsheet Builder is a game-changer in the world of garment decoration, enabling professionals to combine multiple designs efficiently, leading to cost savings and improved turnaround times. By implementing the tips and tricks outlined in this guide, you can enhance print quality and workflow efficiency while embracing the versatility of DTF printing. Staying connected with the community and engaging with new trends will further ensure that you remain at the forefront of DTF technology, achieving exceptional results in your printing endeavors.