The DTF Gangsheet Builder is revolutionizing the way printing businesses streamline their operations and improve product quality. With the explosion of DTF printing techniques, entrepreneurs can utilize this innovative tool to create stunning custom apparel that meets current market demands. By integrating gang sheet design tips into their workflow, print shops can optimize their resources and reduce material waste, leading to significant cost savings. As DTF printing trends continue to evolve, leveraging such strategies becomes essential for staying competitive in a bustling industry. This article explores the multitude of benefits the DTF Gangsheet Builder offers, providing insights that can enhance your print business strategies.

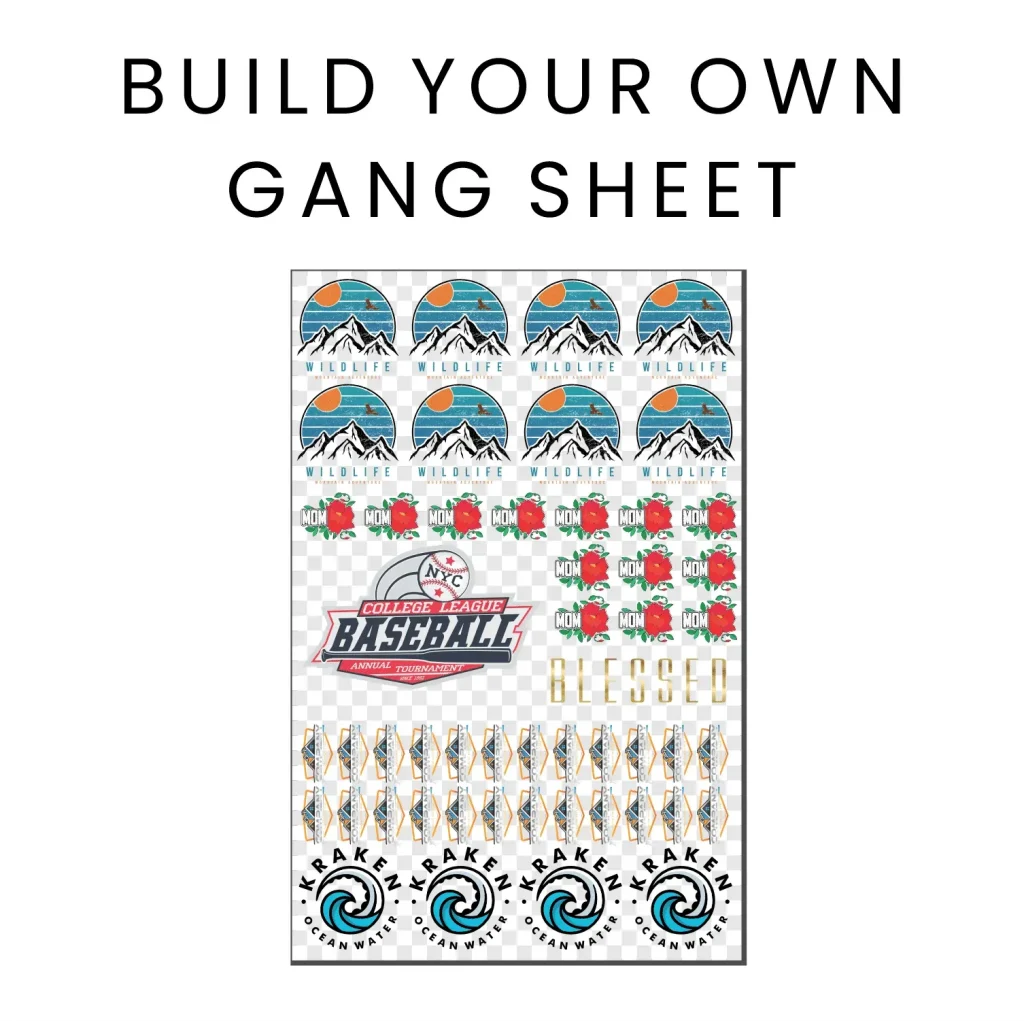

Introducing the DTF Gangsheet Builder opens up a myriad of possibilities for those in the custom printing sector. This powerful tool streamlines production by allowing multiple designs to be printed on a single sheet, a technique that not only increases efficiency but also promotes sustainability within the print business. As demand for personalized merchandise grows, the ability to create high-quality prints through effective gang sheet design becomes increasingly relevant. By utilizing advanced DTF printing technology, print businesses can confidently adapt to shifting market trends and cater to evolving consumer preferences. Therefore, understanding the principles behind effective design and resource management is crucial for any print professional looking to thrive in this dynamic landscape.

Understanding DTF Printing Techniques

DTF printing techniques have revolutionized the way custom apparel is produced, allowing for vibrant colors and intricate designs to be seamlessly transferred onto various fabrics. The key lies in the specialized transfer films and inks that are utilized in this technology, which not only ensure the adherence of designs but also enhance the longevity of the prints. By adopting DTF methods, print businesses can diversify their offerings, appealing to a broader customer base while maintaining high standards of quality.

Moreover, the adoption of DTF printing techniques allows for a more sustainable approach to custom apparel. Through the use of gang sheets, multiple designs can be printed on one sheet, leading to reduced waste and lower material costs. As businesses recognize the advantages of these techniques, they will be better positioned to adapt to industry trends and consumer demands, ensuring they remain competitive in the rapidly changing print landscape.

Maximizing Efficiency with DTF Gangsheet Builder

The DTF Gangsheet Builder is an innovative tool that can significantly enhance operational efficiency within print businesses. By allowing printers to arrange multiple designs on a single sheet, businesses can maximize their use of inks and reduce the overall cost of production. This tool not only streamlines the printing process but also minimizes material waste, ensuring that every inch of film is put to good use.

In addition to cost savings, the DTF Gangsheet Builder simplifies the workflow in print shops. With the ability to easily manipulate designs and layouts, print operators can quickly adapt to client requests or last-minute changes without compromising on quality. This rapid response capability not only improves customer satisfaction but also increases overall productivity, allowing businesses to handle a higher volume of orders with ease.

Effective Design Optimization Tips

Design optimization is a crucial step in achieving exceptional results with DTF printing. Utilizing layout software aids in ensuring designs are positioned accurately on the gang sheet, preventing mishaps that can lead to wasted materials and time. By employing tools like Adobe Illustrator or other specialized DTF applications, designers can meticulously manage the placement of each graphic to maximize the use of available space.

Proper spacing and alignment are also vital components of design optimization. Keeping a consistent margin between designs not only facilitates cutting but also enhances the aesthetic appeal of the finished product. Taking the time to refine these details ultimately leads to higher-quality prints, which can boost customer satisfaction and encourage repeat business.

Innovative Inking Techniques for Vibrancy

The selection of high-quality inks is fundamental for achieving vibrant prints in the DTF process. Businesses should invest in inks that are known for durability and compatibility with their printer models to ensure the best possible adherence and color representation. Brands offering specialized DTF inks often produce more vivid colors and superior results, which can make a significant difference in customer satisfaction.

Furthermore, experimenting with various inking techniques, such as layering colors, can enhance the depth and richness of the prints. By varying the opacity and blending modes in design software, printers can create stunning, multi-dimensional designs that stand out in a competitive marketplace. These innovative approaches not only captivate customers but also help businesses establish a unique identity within the printing industry.

Mastering Printing and Transfer Techniques

Precision is key in mastering printing and transfer techniques in the DTF printing process. The right temperature settings on a heat press are critical; ensuring that the press operates within the ideal range of 320°F to 350°F can greatly impact the final print quality. Consistency in pressure during the transfer process also plays a vital role in achieving even results, which is essential for maintaining brand reputation.

Post-transfer techniques, such as the choice between hot and cold peeling, also significantly affect the final output. Each method has its pros and cons, and understanding these nuances allows printers to choose the technique that best aligns with their specific needs. Mastering these details can elevate the quality of prints and help to secure customer loyalty by consistently delivering high-caliber products.

Staying Ahead with DTF Printing Trends

As the landscape of the printing industry evolves, staying informed about DTF printing trends is vital for maintaining competitiveness. Engaging with industry publications, attending webinars, and networking within community forums can provide insights into emerging technologies and customer preferences. This proactive approach enables businesses to quickly adapt their offerings and practices, ensuring they do not fall behind in a rapidly shifting market.

Moreover, understanding and leveraging trends such as personalized branding and sustainable practices can create unique selling propositions for print businesses. By aligning product offerings with current consumer demands, businesses can attract more clientele and achieve growth. This strategic adaptability will secure a company’s position as a leader within the DTF printing sector.

Frequently Asked Questions

What is a DTF Gangsheet Builder and how does it enhance custom apparel printing?

A DTF Gangsheet Builder is a software or tool designed to optimize the layout of multiple designs for Direct to Film (DTF) printing. It enhances custom apparel printing by allowing print businesses to combine various designs on a single sheet, maximizing efficiency and reducing costs. This approach not only minimizes waste but also streamlines the production process, leading to quicker turnaround times and improved profit margins.

How can I effectively use DTF gang sheets for print business strategies?

To effectively use DTF gang sheets in your print business strategies, focus on design optimization, proper layout arrangement, and spacing. Utilize design software to arrange multiple designs efficiently on one gang sheet and maintain adequate margins between each design. This not only ensures quality prints but also maximizes film and ink usage, which will reduce your overall material costs.

What are some essential gang sheet design tips for DTF printing?

Essential gang sheet design tips for DTF printing include maintaining proper alignment, optimizing spacing, and ensuring designs do not overlap. Using professional design software can help you achieve these points effectively. Additionally, remember to keep consistent margins and utilize color layering techniques to enhance the vibrancy of your final prints.

What DTF printing trends should my business follow to stay competitive?

To stay competitive in the printing industry, follow trends such as the increasing demand for personalization, sustainability in materials, and advancements in DTF printing technologies. Staying updated on market trends through industry publications, webinars, and community forums will help you adapt your DTF printing strategies to meet changing consumer preferences.

What are the benefits of using high-quality DTF inks in my printing process?

Using high-quality DTF inks in your printing process provides several benefits including improved color vibrancy, enhanced durability of prints, and better adhesion to various substrates. High-quality inks ensure that your designs stand out and withstand the test of time, ultimately resulting in higher customer satisfaction and repeat business.

What role do printing and transfer techniques play in DTF printing success?

Printing and transfer techniques play a crucial role in the success of DTF printing. Proper calibration of temperature and pressure settings during the heat transfer process ensures even and lasting adhesion of designs onto garments. Additionally, mastering peeling techniques—whether hot or cold—affects the final appearance of prints, making it essential for achieving quality results.

| Key Points | Details |

|---|---|

| Understanding DTF Technology | DTF printing produces vibrant designs on various substrates, optimizing material use through gang sheets. |

| Benefits of DTF Gang Sheets | Allows multiple designs per sheet, reducing waste and costs while maximizing printer efficiency. |

| Design Optimization | Utilizing design software and proper spacing enhances product quality while preventing misprints. |

| Inking Techniques | Choosing high-quality inks and layering colors can improve vibrancy and adherence of prints. |

| Mastering Printing Techniques | Correct temperature, pressure, and peeling techniques are crucial for successful transfers. |

| Market Demand Insights | E-commerce growth drives demand for custom printing, making DTF technology advantageous. |

| Resource Management | Efficient resource use and learning from industry best practices can enhance profitability. |

Summary

DTF Gangsheet Builder is revolutionizing the print business landscape by introducing innovative techniques that enhance operational efficiency and print quality. By leveraging DTF technology, businesses can produce vibrant, full-color designs while minimizing waste through the effective use of gang sheets. Mastering the design process with professional software, managing inks for explosive color, and perfecting print and transfer methods are all critical strategies that lead to significant cost savings and improved marketability. As the demand for personalized products continues to climb, utilizing these strategies not only positions your business for success but also ensures that you are responsive to the evolving needs of consumers.