The DTF gangsheet builder puts complex multi-design planning into a simple, scalable workflow for apparel printing. By orchestrating DTF gangsheet sizing grids and DTF sizing grids, it helps you maximize fabric coverage and minimize waste across runs. A well-designed system also aligns with your production layout, ensuring consistent color and placement from one sheet to the next. With a reliable approach to the sheet layout, you can standardize processes, reduce manual errors, and speed up setup. In short, this approach leads to more efficient production and a streamlined print workflow.

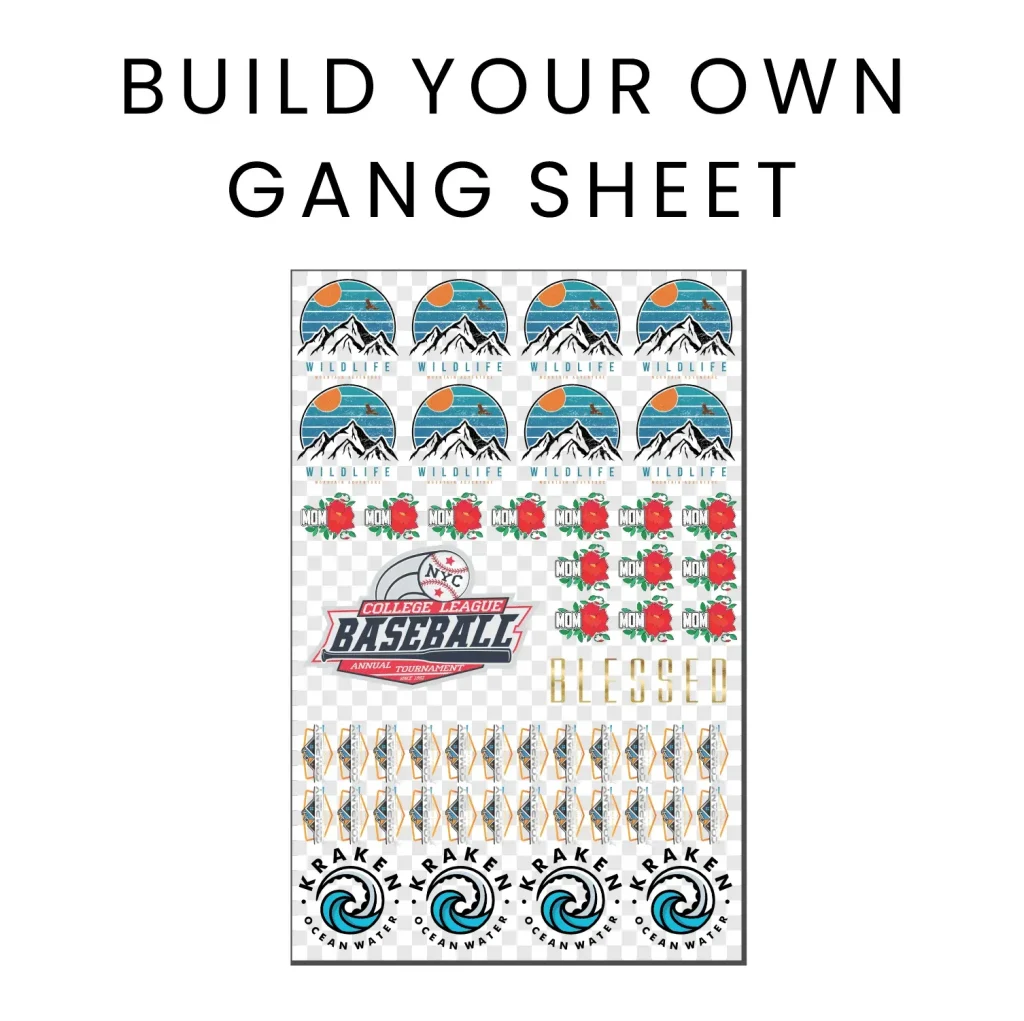

Looking beyond the brand terms, the concept centers on planning multi-design transfers on a single substrate through a grid-based system. Think of a master layout map that slots designs by size, orientation, and color blocks to maximize material use. In practice, designers rely on templates and presets to quickly assemble repeatable batches, ensuring consistency across runs. When integrated with your design software and printing hardware, this approach smooths the workflow, reduces errors, and accelerates throughput.

1. Maximizing Fabric Coverage with DTF Sizing Grids

DTF sizing grids are the backbone of an efficient gangsheet, turning a single sheet into multiple, accurately sized designs. By aligning designs by size, orientation, and spacing, you maximize fabric coverage while keeping color integrity intact. When used correctly, DTF gangsheet sizing grids reduce misprints and ensure that every chip of transfer material contributes to a finished garment.

To maximize sheet usage, start with careful planning of sheet size and cell dimensions. Define margins and bleed so edge-to-edge designs print cleanly, and set consistent gutters to prevent ink bleed between designs. With precise alignment and a high-resolution workflow, you’ll achieve predictable results across batches, making DTF sizing grids a reliable driver of throughput and waste reduction.

2. DTF Gangsheet Builder: From Concept to Production

A DTF gangsheet builder translates creative ideas into machine-ready layouts, transforming sketches into a scalable production plan. This tool helps you draft a gangsheet grid template that accommodates the largest design plus required margins, then scales down for smaller sizes without losing alignment. When you use a dedicated gangsheet builder, you gain a repeatable process that supports both small runs and larger campaigns.

With a robust DTF gangsheet builder, you can plan, test, and reuse configurations across jobs. Features like automatic alignment, grid templates, and export options preserve grid structure across design software and printer workflows. This paves the way for DTF print workflow optimization, letting teams move from concept to production with fewer manual adjustments and less rework.

3. Design Prep and Grid Margin Strategy for Accurate Alignments

Effective design prep starts long before the printer fires up. Collect artwork, note intended garment sizes, and decide if designs will be rotated or mirrored. This planning phase feeds into the gangsheet grid template, ensuring each design lands in its designated cell with consistent spacing and orientation. A disciplined prep process reduces surprises during production and preserves the integrity of the final prints.

Margins, bleeds, and alignment are the levers that ensure accuracy. Establish reliable margins to prevent clipping and set bleed to cover edge-to-edge coverage when required. Maintaining pixel-perfect alignment is crucial for multi-color designs, gradients, or overlays, especially when using DTF garment printing layout concepts that require precise transfer positioning and color fidelity.

4. Creating a Reusable Gangsheet Grid Template for Consistency

A gangsheet grid template acts as a blueprint for repeatable success. By defining common sheet sizes, cell dimensions, margins, and bleed zones, you create a foundation that speeds up project setup and preserves accuracy across runs. Using a well-designed gangsheet grid template helps you scale from a single design to many without sacrificing consistency.

Reusable templates also streamline collaboration among designers, printers, and operators. When templates are shared, you reduce the risk of human error and ensure that color management, resolution, and layout rules stay uniform. In practice, a template supports DTF sizing grids and even guides the team toward better DTF print workflow optimization through standardized steps and predictable outputs.

5. Adapting Grids Across Garment Lines: T-Shirts to Hoodies

Different garment lines demand tweaks to grid configurations. Adult tees may prioritize chest-area designs and straightforward vertical alignment, while hoodies or kids’ shirts require adjustments to cell size and spacing to fit unique print areas. A capable DTF gangsheet builder allows multiple grid configurations and saves them as presets, enabling quick switching without sacrificing precision.

This flexibility supports a steady DTF garment printing layout across a production queue. By preconfiguring grid presets for various product lines, you ensure consistent sizing grids that still accommodate variations in sleeve length, torso height, and print area. The result is reliable batch outputs and an efficient path from design to finished apparel.

6. Automation and Quality Assurance in DTF Sizing Grids

Automation minimizes manual intervention and helps enforce grid integrity. Integrated checks can verify that designs stay within their cells, margins meet thresholds, and bleeds are correctly applied. A well-designed workflow reduces variance and speeds up throughput, especially in high-volume operations where consistency is critical.

Quality assurance goes beyond automation. Regular test prints on actual transfer films and fabrics confirm color accuracy, alignment, and heat transfer performance. Documented grid configurations, margins, and color profiles become the backbone of reproducible results, enabling ongoing improvements and reliable DTF print workflow optimization across multiple campaigns.

Frequently Asked Questions

How does the DTF gangsheet builder optimize DTF gangsheet sizing grids and sheet usage?

The DTF gangsheet builder helps you plan sheet size, define grid cells, and set margins, bleeds, and spacing to align designs across the grid. It translates ideas into a machine-ready DTF layout, maximizing the number of garments per sheet while preserving color accuracy. For best results, design at high resolution (typically 300 DPI or higher) and maintain consistent color management as you populate the DTF sizing grids.

What is a DTF sizing grid and why is it crucial in a gangsheet grid template?

DTF sizing grids define the individual cells within the gangsheet that map to each target size and orientation. They ensure each design prints within its designated cell, maintaining baseline alignment and preventing overlap or clipping. A well-considered DTF sizing grid is essential for consistent colors, accurate garment placement, and efficient production in your gangsheet grid template.

How can I reuse a gangsheet grid template across multiple orders to boost DTF print workflow optimization?

Save your grid as a gangsheet grid template preset for common sheet sizes and design counts. Reusing a template preserves cell dimensions, margins, and bleed settings so you only swap artwork between runs. This accelerates setup, maintains alignment, and supports streamlined DTF print workflow optimization across orders.

What should I consider when designing a DTF garment printing layout with multiple designs?

In a DTF garment printing layout, account for the target garment types and print areas, ensuring grid cell sizes accommodate the largest designs plus margins and bleed. Maintain consistent orientation and spacing to simplify production, and manage color profiles and print marks within the template to guard against misalignment during transfer.

How does automation in the DTF gangsheet builder impact workflow optimization?

Automation adds checks for grid integrity, verifies designs stay within their cells, and ensures margins and bleeds meet thresholds. It also improves file organization and archiving, making it easier to reuse proven gangsheet configurations and achieve higher throughput with fewer errors—key benefits for DTF print workflow optimization.

What are common pitfalls when using a gangsheet grid template and how can they be avoided?

Common issues include inconsistent margins, insufficient bleed, low-resolution artwork, color management gaps, and overcrowding of designs. Avoid them by using a fixed gangsheet grid template with defined cell sizes, conducting test prints on real transfer films, maintaining precise measurements, and documenting grid settings for future runs.

| Topic | Key Points | Notes / Examples |

|---|---|---|

| Introduction to DTF printing | DTF printing transforms apparel production with vibrant results and flexible production scales; the gangsheet boosts speed, consistency, and reduces waste. | Baseline context for mastering gangsheet layouts. |

| Gangsheet concept | A gangsheet is a single print containing multiple designs arranged in a grid to maximize sheet usage while maintaining color alignment. | Core idea for efficient production. |

| Sizing grids components | Key factors: grid dimensioning; margins/bleed; spacing; alignment; resolution and color management. | Define sheet size, margins, bleed, and ensure color fidelity. |

| Step-by-step guide (summary) | Plan designs; choose grid dimensions; set margins/bleed; place designs; verify alignment; add color marks; export; test print; reuse templates. | Practical workflow outline. |

| Practical tips | Maintain consistent toolchain; precise measurements; garment placement; test with real materials; document processes. | Tips for accuracy and efficiency. |

| Common pitfalls | Inconsistent margins; inadequate bleed; low-resolution art; ignoring color management; overcrowding. | Common causes of misprints. |

| Templates, tools, and efficiency gains | Gangsheet grid templates; grid templates; automatic alignment; export options; consistent reuse across software and printer workflows. | Templates speed up setup and ensure consistency. |

| Tailoring to garment lines | Create multiple grid configurations and presets for different products (adult tees, kids’ shirts, hoodies, etc.). | Presets help maintain consistency across product lines. |

| Automation and workflow integration | Automate checks, file organization, and reuse configurations to scale for high-volume operations. | Automation boosts throughput with maintained quality. |

Summary

DTF gangsheet builder platforms enable printers to turn multiple designs into a single, repeatable workflow. By understanding gangsheet layouts and mastering sizing grids, you can maximize sheet usage, reduce waste, and streamline production. Plan with a robust gangsheet grid template, and maintain disciplined margins, bleeds, and alignment to ensure consistent results. As you work with DTF gangsheet sizing grids and related concepts like DTF sizing grids and gangsheet templates, you’ll improve accuracy and efficiency. Remember to test, document, and reuse proven configurations to sustain high-quality DTF garment printing layouts and beyond.