Georgia DTF trends are reshaping the landscape for regional apparel production, with brands and print shops retooling workflows to deliver faster turnaround, sharper color, and greater flexibility in garment decoration, while also influencing how small businesses position themselves in a competitive market, a convergence that is reshaping supplier relations, training pipelines, and brand value in the process. Across Georgia DTF printing operations, studios are balancing the promise of on-demand runs with the realities of setup, cost, lead times, and consistency, a dynamic that mirrors broader industry trends observed in the market and that pushes providers to streamline workflows, invest in training, and offer scalable options for diverse client needs; Providers are also refining color management pipelines and offering robust training to ensure consistent results across devices and fabrics. AI design in textiles is becoming a catalyst for experimentation, allowing designers to generate, compare, and refine motifs before transfer, which accelerates decision-making, reduces material waste, and opens doors to more complex patterns that still print reliably on a variety of fabrics. DTF finishes are increasingly used to differentiate products through tactile feel and visual effect, with options ranging from soft-hand to glossy or matte textures that suit Georgia brands’ identities, end-use contexts, and care routines, while also aligning with sustainability considerations and solvent-reduction goals. For businesses targeting local markets, custom apparel printing Georgia is expanding access to customized lines, team uniforms, and event merch, leveraging AI-driven design, advanced film systems, and flexible licensing models to maintain quality across small runs, bid for brand consistency, and build lasting relationships with Georgia retailers and influencers; This alignment also supports partnerships with industry groups and education programs that nurture local talent.

Viewed through an LSI lens, the trend in Georgia resembles a broader movement toward film-transfer technology and digital textile printing that supports on-demand apparel decoration. Industry chatter emphasizes not just the mechanics of transfer, but related ideas such as color management, textured finishes, sustainable formulations, and AI-assisted design pipelines that collectively shape consumer-facing outcomes. For brands and shops in Georgia, this broadened vocabulary—regional adoption of DTF practices, AI-driven design workflows, and flexible finishes—helps align conversations with clients and search engines alike, making it easier to surface services like custom manufacturing, small-batch printing, and local collaborations.

Georgia DTF Trends: AI-Driven Design, Color Fidelity, and Fast Turnaround

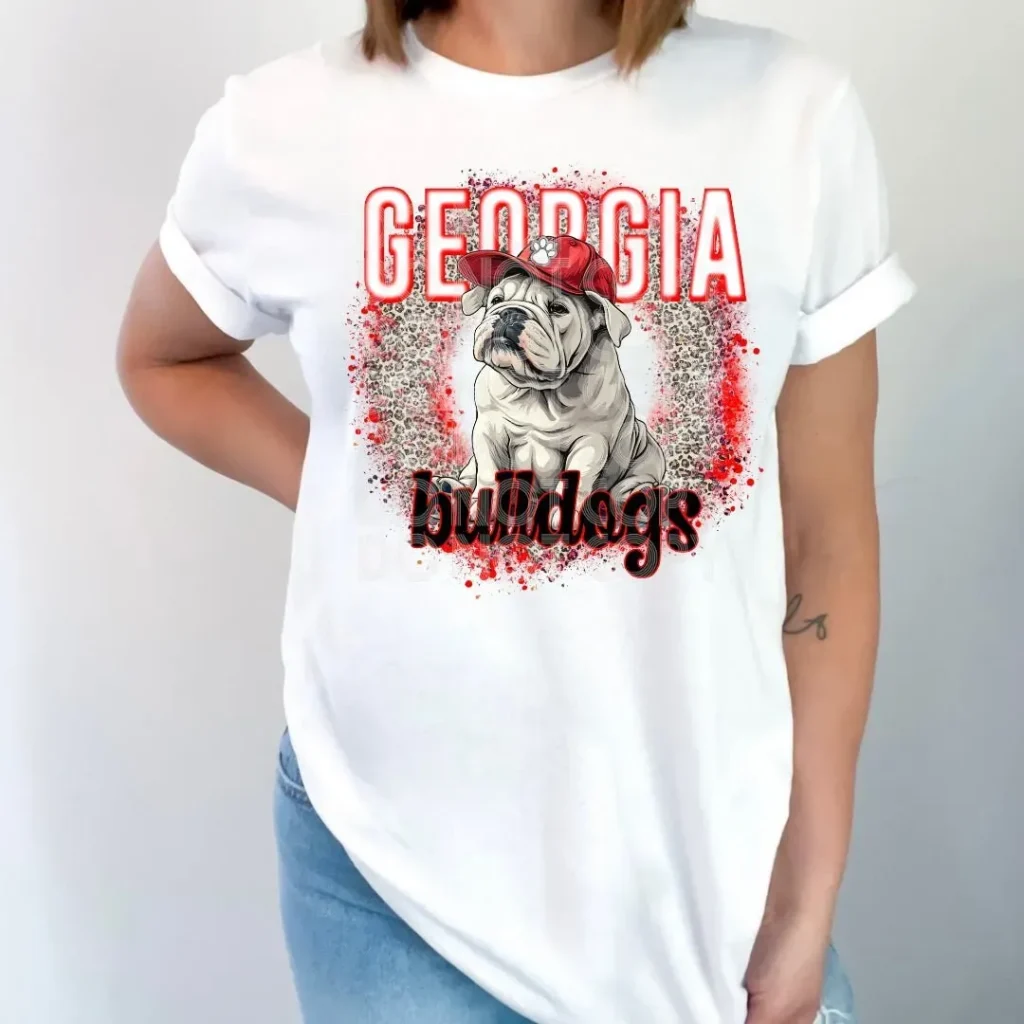

Georgia DTF trends are shaping the regional market by blending textile heritage with digital innovation. Printer shops across Georgia report faster turnaround times, richer color fidelity, and growing comfort with a wider range of fabrics—from cotton tees to performance blends. This trend line mirrors the national move toward direct-to-film printing for short runs while emphasizing local supply chains, education, and collaboration with Georgia-based brands.

AI design in textiles is a major accelerant for these trends. By enabling rapid ideation, color optimization, and layout planning before any film is produced, AI tools help Georgia DTF printing studios experiment with dozens of concepts and land on options that translate cleanly through film transfer and finishing. The result is faster go-to-market timelines, consistent results, and more distinctive branding for local retailers, teams, and event organizers.

AI Design in Textiles: Transforming Custom Apparel Printing Georgia

AI design in textiles is shifting how Georgia studios approach graphics. Software can generate variants, refine textures, and optimize color palettes, letting designers explore complex patterns without multiple manual redraws. For custom apparel printing Georgia clients, this means more options and faster previews, with outputs ready for transfer planning and production.

As AI-driven workflows mature, pattern usability and fabric-aware optimization improve, reducing waste and increasing the success rate of transfers on diverse fabrics. The Georgia market benefits from tighter collaboration between designers and printers, better branding consistency, and a broader palette of options that align with DTF printing trends and local fashion sensibilities.

DTF Finishes: Texture, Durability, and Sustainable Options in Georgia

DTF finishes extend the base graphic with tactile and visual nuance. In Georgia, gloss, matte, and soft-hand finishes are chosen to match brand identity, team colors, or product lines, with film choice and curing conditions shaping the final hand feel and drape.

Sustainability is reshaping finish choices as brands seek lower energy use and fewer solvents. Georgia printers are testing eco-friendly formulations and efficient curing to improve washfastness and resistance to cracking, while preserving vibrant colors and comfortable hand feel.

Material Diversity and Small-Batch Efficiency in Georgia DTF Printing

DTF works across a broad fabric spectrum in Georgia—from 100% cotton to blends and performance textiles—supporting local fashion labels, collegiate gear, and event merchandise with flexible mini runs.

Small-batch efficiency is a primary driver of value. Short-run DTF printing reduces inventory risk and enables rapid iteration, while color management pipelines, ICC profiles, and fabric testing help ensure consistent color, edge sharpness, and wash durability across Georgia DTF printing. This aligns with broader DTF printing trends in Georgia, where printers optimize color management and fabric testing to maximize quality.

Strategic Playbook for Georgia Shops: Finishes, On-Demand, and Brand Story

A practical playbook blends design briefs, AI-assisted ideation, and controlled print tests. Start by capturing color goals, fabric types, and end-use scenarios; then use AI design in textiles to generate several concept directions before selecting a final option for production. This approach accelerates decision-making for Georgia clients and ensures the chosen graphics translate well to film transfer and finishing.

Pair on-demand capabilities with a strong brand narrative. Emphasize premium finishes, reliable turns, and clear care guidance to justify value for custom apparel printing Georgia customers. Position your shop as a local partner for schools, teams, and boutique brands, while showcasing your expertise in Georgia DTF printing and AI-driven design.

Frequently Asked Questions

What are the current Georgia DTF trends shaping custom apparel printing?

Georgia DTF trends today emphasize high color fidelity, broad fabric compatibility, and a shift toward on-demand short runs for custom apparel printing Georgia. AI design in textiles accelerates concept testing and helps optimize transfers for DTF printing trends. Finishes such as gloss, matte, and soft hand are used to tune texture and durability, while sustainability considerations guide material choices.

How is AI design in textiles influencing Georgia DTF trends and outcomes?

AI design in textiles accelerates Georgia DTF trends by generating multiple concept options, optimizing color palettes, and improving transfer layouts. In Georgia DTF printing, this lowers waste, speeds go-to-market timelines, and improves color fidelity and consistency for custom apparel printing Georgia.

Why are DTF finishes important in Georgia DTF trends, and how should brands choose them?

DTF finishes expand texture and feel, offering gloss, matte, and soft hand options that align with Georgia DTF trends. Brand decisions should consider fabric type, end use, and care; durability and washfastness are key, and eco-friendly finishes are gaining traction for Georgia customers.

Which fabrics and run lengths align with DTF printing trends for custom apparel printing Georgia?

DTF printing works well on cotton and blends, with performance fabrics also common in Georgia markets. The trend toward on-demand and short runs suits custom apparel printing Georgia, schools, teams, and boutique brands. Always test color fidelity and finish performance across target fabrics for Georgia DTF printing.

What practical steps should a Georgia-based shop take to capitalize on Georgia DTF trends?

Georgia-based shops should invest in reliable DTF printing equipment, color management, and workflow controls; run controlled tests to evaluate color, finishes, and wash performance; leverage AI design in textiles to rapidly explore concepts; offer a range of DTF finishes; build relationships with local suppliers and training resources to support Georgia DTF printing and custom apparel printing Georgia.

| Aspect | Key Points |

|---|---|

| Overview / Context | DTF printing has moved from niche to mainstream in Georgia; trends emphasize faster turnaround times, richer color fidelity, flexible finishes, and the growing role of AI in design workflows. |

| AI Design in Textiles | AI design accelerates ideation, color optimization, and pattern usability; enables rapid iterations and consistent results; improves client satisfaction and branding. |

| DTF Finishes | Gloss, matte, soft-hand, and textures; finishes influence durability, texture, and brand identity; sustainability and energy considerations are increasingly relevant. |

| Materials & Landscape | Diverse fabrics (cotton to performance textiles); high-resolution color fidelity; suitable for small runs and on-demand production common in Georgia. |

| Georgia Market | Local industries, suppliers, and training resources; collaboration with designers; shorter lead times; portfolio growth around GA-specific needs. |

| Practical Steps | Use AI-driven concept exploration, run controlled print tests, request swatches for finishes, calibrate color management, build a library of approved materials, leverage on-demand opportunities, and pursue training partnerships. |

| Brand Story & Positioning | Frame AI design and premium finishes as part of a technology-forward narrative; emphasize sustainability and transparency; differentiate through branding. |

| Operational Considerations | Invest in equipment maintenance, color fidelity tools, waste reduction, safety/compliance, and clear customer education on finishes and care. |

| Future Outlook | Expect ongoing AI-driven design advances, more sophisticated finishes and fabric compatibility, on-demand collaboration models with local artists, and stronger emphasis on sustainability and supply-chain transparency. |

Summary

Georgia DTF trends provide a snapshot of how technology, design, and regional demand converge in the state’s print industry. The table summarizes core areas from AI design in textiles to finishes and on-demand production, outlining practical steps and strategic directions for Georgia-based businesses.